Solvay Hikes Soda Ash and Composites in USA

25.09.2019 -

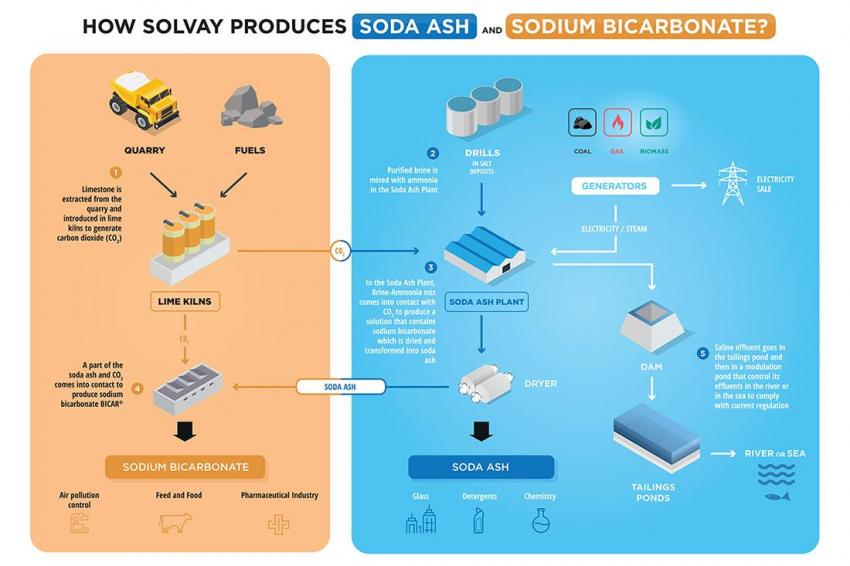

Solvay has announced plans to increase soda ash capacity in Green River, Wyoming, USA, in order to meet long-term global demand growth. The company will also expand sodium bicarbonate output in Devnya, Bulgaria, to meet rising demand worldwide for flue gas treatments.

A total of €185 million is being spent on the two projects, spread over the next three years.

“Soda ash and bicarbonate are highly cash generative and resilient businesses for Solvay. Against a backdrop of growing global demand, these investments will deliver resilient cash and strong returns,” said Christophe Clemente, president of Solvay’s Global Business Unit Soda Ash & Derivatives.

According to Solvay, global demand for soda ash is forecast to grow by 10 million t (excluding China) between 2018 and 2030, with 4 million t between now and 2023. Demand is being driven by export markets in Southeast Asia, Brazil, the Middle East and Africa for manufacturing detergents, flat and container glass, and Latin America for extracting lithium.

At Green River, the company will add 600,000 t/y of soda ash from trona, a naturally occurring mineral. The project will leverage existing infrastructure with the additional production anticipated to start ramping up by the end of 2021.

In Bulgaria, where production is part of an existing 75:25 joint operation with Sisecam, a new line adding 200,000 t/y is expected to be operational by the end of 2020. It will produce Solvair sorbents, which are sodium-based solutions to treat exhaust gases from factories, incineration plants and ships, and BicarZ, a sodium bicarbonate buffer for animal nutrition.

In separate news, Solvay is adding another line to produce thermoplastic composites at its plant in Anaheim, California, USA, to meet strong demand growth from aerospace customers.

With the new line, plus upgrades to existing lines, the Belgium group said it will have multiplied its capacity fourfold since 2016. Solvay did not say when the new line will go into operation.