AkzoNobel Expands In-house Resin Production

Michael Friede, chief commercial officer for performance coatings, explained that while the company produced a “good proportion” of what it needed, it also has to source commodity and other specialty resins from third parties.

“Further investing in our own resin capabilities will help us to secure sustainable business growth, as well as supporting our innovation pipeline and sustainability targets,” he said. “It will enable us to secure raw material supply to optimally support our Grow & Deliver ambitions and, at the same time, we’ll look to generate extra value by leveraging and optimizing the volumes we don’t bring in-house with our network of external partners.”

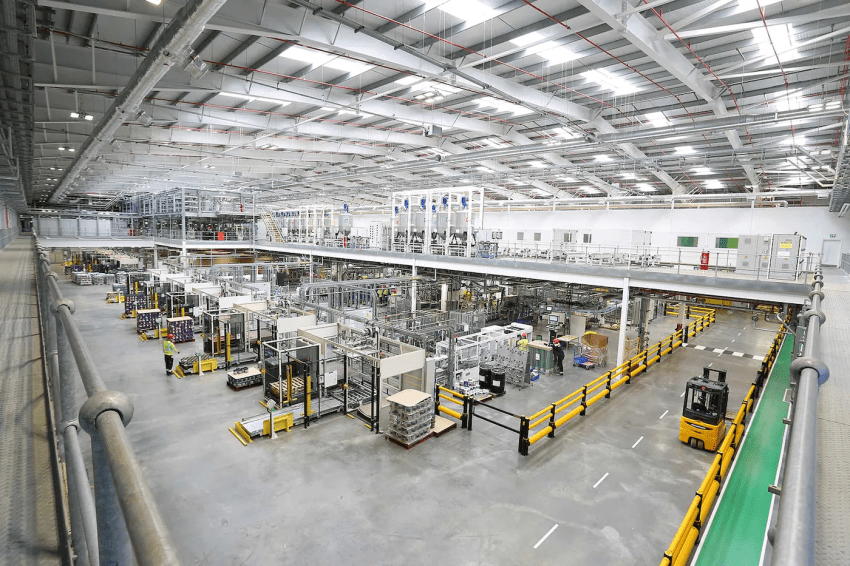

The plans, which include investing in sites, equipment and staff, were developed after the company tasked an internal team to investigate opportunities to unlock more value and make AkzoNobel more self-sufficient. The company did not reveal how much it would spend on the expansion, but said it expects the investment to contribute between €15 million and €20 million in EBITDA by 2023.

“We’re well aware that demand for resins is only expected to increase. Meanwhile, our resin manufacturing sites have extra production capacity available,” Friede said.

A key ingredient in coatings production, resins are used as a binder to hold the pigment particles together and provide adhesion to the coated surface. According to a senior spokesperson, AkzoNobel produces commodity resins such as acrylic, epoxy and polyurethane resins, at 23 sites worldwide.

Author: Elaine Burridge, Freelance Journalist