DART Fieldbus Cranks Up Intrinsically Safe Power

14.04.2011 -

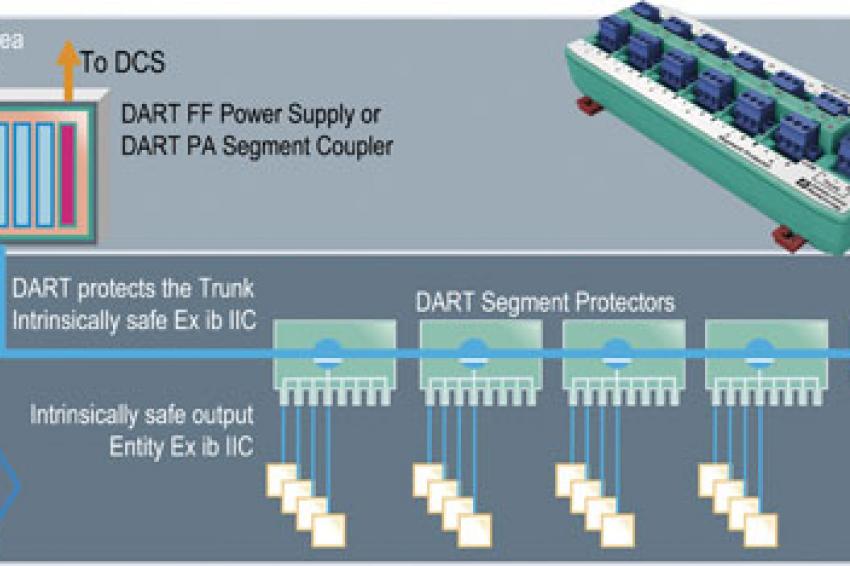

Product - The first real application for DART - Dynamic Arc Recognition and Termination - is DART Fieldbus. It is part of the FieldConnex series of fieldbus infrastructure components by Pepperl+Fuchs. DART technology, which is also known as Power-I and driven by a consortium of 13 companies, enables high power levels while maintaining ignition protection intrinsic safety (I.S.) - the safest way to protect plants in hazardous areas from unintended ignitions and explosions.

DART Fieldbus is made for hazardous area Zone 1 and gas group IIC. It is certified "by the book" through PTB, the German Metrology Institute, according to the standard that is well-known by all hazardous area specialists: IEC 60079-11. And this means the highest degree of protection in hazardous area Zone 1 through intrinsic safety.

For Today's Fieldbus Instrumentation

Real simplicity is built into DART Fieldbus: It offers all the benefits of FISCO, the Fieldbus Intrinsically Safe Concept regarding engineering, application, and maintenance. Only DART Fieldbus enables more than five times the power of current intrinsically safe fieldbus installations - enough to drive long cable lengths and many devices. Ten years ago, with FISCO the acceptance of intrinsically safe fieldbus began with rules simplifying application and validation of explosion protection. And today, DART Fieldbus breaks through even more barriers-lifting the power limits and enabling the greatest freedom of choice:

Existing intrinsically safe fieldbus instrumentation can be applied or remains in place on upgrades.

"Our first idea for DART Fieldbus was to come up with a full I.S. fieldbus segment with the same attributes and power compared to fieldbus in the safe area," said Michael Kessler, technical director, Components and Technology at Pepperl+Fuchs. "This is why DART only protects the trunk. The spurs are intrinsically safe in the classic way. DART Fieldbus can be used for existing I.S. instrumentation." The differences between DART Fieldbus and fieldbus in safe areas are negligible.

Other attributes include physical layer diagnostics and load-sharing redundancy of power supply. Load sharing means that power supplies are controlled to carry exactly half the load current each. This means optimal operating conditions, a longer service life of power supply and higher system availability. DART Fieldbus may well become the best-in-class solution for intrinsically safe fieldbus installations - it has the power, the options, and the experience from the leading innovator and specialist in hazardous area products, Pepperl+Fuchs.

DART has been recognized as a major innovation for the process industry and was one of the top five nominees for the prestigious Hannover Messe International Technology Prize, the Hermes Award. Only two years after the nomination, Pepperl+Fuchs puts this technology into practice and products.

"It fills us with pride to have been recognized in this way," Kessler said. "We are looking to create a solution that is practical and easy to apply."

Risk Reduction Included

Lifting Power Limits

- Intrinsic safety with more power

- Long cable runs: Up to 1,000 m trunk / up to 120 m spur

- Optional Advanced Diagnostics for the physical layer

- Up to 32 instruments per segment

- Designed and conformant to standards for explosion protection IEC 60079-11