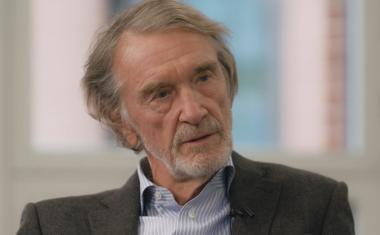

Expert Statement: Andreas Bonhoff, TTP Group

ISPE and its members are developing the roadmap to introduce Industry 4.0, also called the Smart Factory, at the pharmaceutical industry as Pharma 4.0 – an operating model that is interconnected, meaning that the digital tools allow for a fully connected network to enable direct communication between all levels in an organization.

Despite the transformational potential of digitalization, the pharma industry has historically been slower than other sectors in adopting digital tools, such as cloud storage, artificial intelligence (AI), machine learning (ML), blockchain, and remote communication technologies, and in making associated changes in workplace culture and strategic priorities. Now, however, the Covid-19 pandemic may be accelerating the pace of change.

What are the digitalization trends in the industry? What is the business case to develop and implement digital tools and digitalization strategies? And how can organizations introduce and use them?

CHEManager asked executives and industry experts to share their views on digitalization trends in the pharmaceutical industry and challenges on the way to realize the sector’s digital transformation. We proposed to discuss the following aspects:

- What do you think are the key digitalization trends in the pharmaceutical industry?

- What do you consider to be the most important benefits of digitalization in the pharmaceutical industry?

- Is your company involved in systematic, ongoing action to digitalize operations?

- At present, digitalization in the pharmaceutical industry is immature. In your view, what are the biggest obstacles that need to be overcome in the digitalization of the sector?

- How would you rate the digital maturity level of your company?

“We have systematized the digitalization of processes

by deploying specialized teams

in the development departments.”

Andreas Bonhoff: The planning of all technical projects of TTP Group is based on the building information modeling (BIM) approach. The trend is towards seamlessly integrated planning across all disciplines under one roof. This minimizes replanning efforts as well as costs and enables the creation of a digital twin of the plant. Actually, already part of our daily work.

To meet the BIM requirements for each project and define the scope and benefits, it is necessary to work closely with the client. It is critical that the process is considered as a whole and that the information/data requirements are coordinated and agreed upon by both parties. Through the BIM approach, changes in all phases of the building's life cycle are immediately visible to all parties and the impact is synchronized immediately.

During the construction phases, BIM provides contractors with data information that is shared via cloud data platforms, helping them save both time and money. In addition, construction managers can also track and control the entire construction progress using augmented reality.

At TTP Group, we have systematized the digitalization of processes by deploying specialized teams in the development departments. For example, at Pharmaplan, the Digital Factory department is divided into different areas that are responsible for the development of digitalization – which is unique: Digital Engineering Building, Digital Engineering MEP & Process, and Manufacturing IT & Automation. We use a cloud-based platform called BIM360 as our common BIM data environment, which allows us to share the work with all project participants as well as with our client. It provides not only the data management system, but also all relevant building data that is geometrically visualized as a virtual composite model and stored in a live database. Only in this way, the correct implementation of the BIM database from conception to facility management activities can succeed.