Expert Statement: Girish Malhotra, EPCOT International

Executives and industry experts share their views on drivers as well as barriers for the use of flow chemistry in pharmaceutical manufacturing and the prospect for this technology in their industry sector.

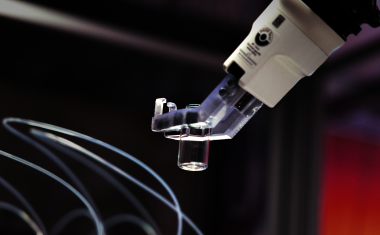

Continuous Manufacturing (CM) — also called Flow Chemistry or Micro Reaction Technology (MRT) — is a technique that has been gaining global importance over the past decade as a result of improved process control and reduced operating costs, leading to increased manufacturing profits and a competitive edge. Recent years have shown that the reason for a company to change from “batch” to “flow” have been varied, often depending on the sector, process type of interest and scale of operation. Supply chain security and improvements in process sustainability are strong emerging drivers for the adoption of CM.

With the product key, the infrastructure needed varies greatly and depends on the available chemistry, cost of goods, volumes required and the hazard profile of a transformation. The modularity and flexibility of continuous flow set-ups enables the development of small, agile production plants that can be used for the manufacture of multiple products — with easy re-configuration allowing for rapid product changeover.

Following on from this, the ease of replicating these small footprint systems represents an opportunity for manufacturers to develop a process and subsequently deliver production units across multiple countries to serve the local product demands. This is in stark contrast to the current approach of a single large-scale plant, with warehousing used to manage supply chain disruptions.

With all of these benefits, a logical question follows: Why the slow adoption of MRT?

CHEManager asked executives and industry experts to share their views on drivers as well as barriers for the use of flow chemistry and the prospect for this technology in their industry sector. We proposed to discuss the following aspects:

- In your opinion, what are the strongest drivers (success factors) of the implementation of flow chemistry processes?

- Which barriers are slowing down or impede the implementation of flow chemistry processes?

- What does it need for flow chemistry to be implemented more widely?

In my opinion, under the current business model drivers to implement microreactor/flow technology at brand and generic companies do not exist unless companies in each sector make a concerted effort to evaluate and incorporate them. Incorporation of better manufacturing technologies has to be internally driven. A business model change would be necessary and will have to be justified.

For companies in each sector (brand and generic) to implement these technologies, chemistry, process development and manufacturing has to be thought through and done differently from the current methods. Process design chemists and chemical engineers have to be involved from the onset. Their collaborative creativity has to be used and is a must.[1] For inclusion of improved processes for existing and new products, companies have to guarantee product performance and quality. Educating regulators about process design will slow approval and commercialization. It is going to be a challenge and a waste of time. Faster regulatory approval could lead to quicker adoption of better technologies and higher profits. If companies guarantee product performance and quality, regulatory interference has to be minimum – a highly unlikely expectation.

“Faster regulatory approval could lead to quicker adoption of better technologies and higher profits.”

Since most processes and equipment designs are product specific, lack of product volume is the largest deterrent for investment in such technologies. For the brand drug companies investing in better manufacturing technology for a drug under patent will be a challenge. Time and money needed for re-approval will be a deterrent. Due to short patent life and a time consuming regulatory approval process, companies will not invest unless companies commit to producing the product after patent expiration. Under the current business model incorporation of these technologies is highly unlikely. Another deterrent is equipment utilization. Current utilization is about 45-55%. Since flow chemistry based process designs are very product specific, their equipment utilization will be still lower – an additional deterrent for such investment.

Microreactors are helpful and work well in carefully designed plants that have the necessary production volume to operate year round, a real continuous process. There are other equipment configurations that cost as much as 50-60% less and work equally well or better in a properly designed plant. We commercially used such equipment from 1970 onwards. If companies insist on using microreactors and associated equipment and do not have the production volume to operate year round, they will have to change their business model and operating strategies. For brand companies, this is highly unlikely due to their profitability. Generics can do it. However, it is possible that the current generic drug landscape may not allow such a change. “Outliers” can make the necessary change. Microreactors could be used to manufacture brand products, but for their long-term use, the business model needs to be changed, as mentioned earlier, due to high investment costs and product-specific designs. A highly unlikely speculation.

[1] Malhotra, Girish: Active Pharmaceutical Ingredient Manufacturing: Nondestructive Creation