Expert Statement: Mark Muldowney, Sterling Pharma Solutions

Executives and industry experts share their views on drivers as well as barriers for the use of flow chemistry in pharmaceutical manufacturing and the prospect for this technology in their industry sector.

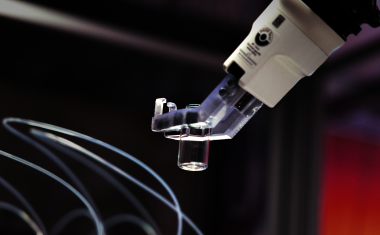

Continuous Manufacturing (CM) — also called Flow Chemistry or Micro Reaction Technology (MRT) — is a technique that has been gaining global importance over the past decade as a result of improved process control and reduced operating costs, leading to increased manufacturing profits and a competitive edge. Recent years have shown that the reason for a company to change from “batch” to “flow” have been varied, often depending on the sector, process type of interest and scale of operation. Supply chain security and improvements in process sustainability are strong emerging drivers for the adoption of CM.

With the product key, the infrastructure needed varies greatly and depends on the available chemistry, cost of goods, volumes required and the hazard profile of a transformation. The modularity and flexibility of continuous flow set-ups enables the development of small, agile production plants that can be used for the manufacture of multiple products — with easy re-configuration allowing for rapid product changeover.

Following on from this, the ease of replicating these small footprint systems represents an opportunity for manufacturers to develop a process and subsequently deliver production units across multiple countries to serve the local product demands. This is in stark contrast to the current approach of a single large-scale plant, with warehousing used to manage supply chain disruptions.

With all of these benefits, a logical question follows: Why the slow adoption of MRT?

CHEManager asked executives and industry experts to share their views on drivers as well as barriers for the use of flow chemistry and the prospect for this technology in their industry sector. We proposed to discuss the following aspects:

- In your opinion, what are the strongest drivers (success factors) of the implementation of flow chemistry processes?

- Which barriers are slowing down or impede the implementation of flow chemistry processes?

- What does it need for flow chemistry to be implemented more widely?

Mark Muldowney: It is important to remember that flow chemistry is not a ‘one size fits all’ technology for chemical manufacturing, and not every process will be relevant for flow chemistry at commercial scale. However, one of the greatest benefits it offers is through safety when handling highly potent and hazardous or highly reactive species, as it reduces the risk of exposure to operators and scientists by having smaller quantities of materials within the reaction vessel at any one time.

“Flow chemistry is not a ‘one size fits all’ technology

for chemical manufacturing.”

The technology broadens the toolkit for development chemists and should be seen very much as complementary to batch manufacturing, rather than a replacement. Its use allows the variation and control of scale-up conditions for manufacturing and provides access to new chemical reaction space through higher temperatures, pressures, concentration, and kinetics. From a process control and material quality standpoint, developing a flow reactor and specific reaction parameters that can be constantly monitored and adjusted within a defined range can ensure a more consistent product specification. Flow synthesis also generates new development opportunities based upon utilizing biocatalysis and heterogenous catalysts, as well as electrochemical oxidation and reduction, where the technology could be advantageous to improve not only chemical selectivity and quality, but also to avoid exposure to toxic intermediates. Additionally, photochemistry lends itself perfectly to flow chemistry, where there is a move away from traditional routes that use metal catalysts, and opens up new methodologies that are cleaner, more energy efficient and cheaper to run at scale. Using flow chemistry also allows the design of potentially integrated multi-step chemical synthesis.