Fueling the Circular Carbon Economy

Interview with Florian Hildebrand, Greenlyte Carbon Technologies

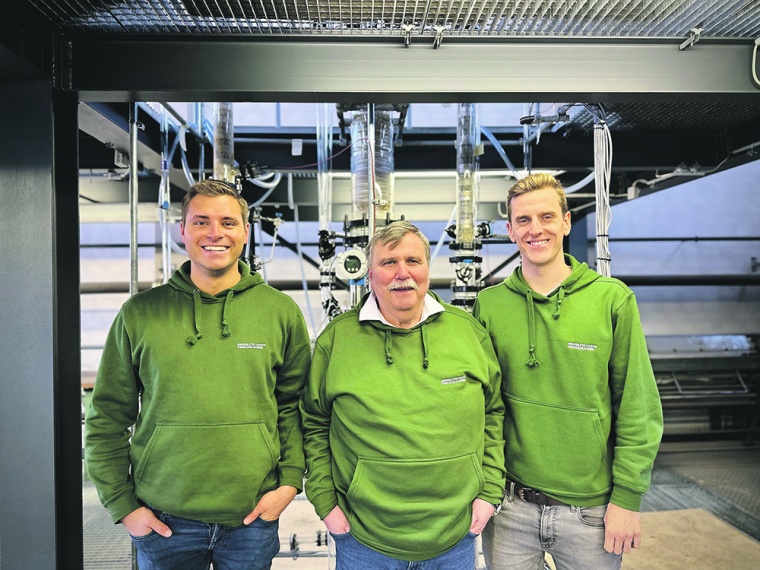

In this interview, we speak with Florian Hildebrand, the CEO and co-founder of Greenlyte Carbon Technologies. Greenlyte has developed a breakthrough direct air capture (DAC) technology, which can extract CO2 from ambient air and turn it into green hydrocarbons. Hildebrand discusses the company‘s mission to free the world from fossil fuels, relevance to the fight against climate change, current status, future plans, and how the team came together.

CHEManager: What does Greenlyte Carbon Technologies do?

Florian Hildebrand: Greenlyte Carbon Technologies aims to free the world from fossil fuels by fueling the circular carbon economy. Our breakthrough direct air capture —DAC — technology extracts CO2 from ambient air and converts it into green hydrocarbons. We believe that our technology is a crucial step towards de-carbonizing industries such as the chemical industry, energy storage, and transportation. Renewable hydrocarbons are required to power these sectors sustainably, and our DAC technology provides a renewable and sustainable source of energy. We sell our technology to customers in the form of modular containers, which makes it highly adaptable and versatile.

Why is it relevant what Greenlyte does?

F. Hildebrand: Climate change is one of the most significant challenges facing humanity, and de-carbonizing as much as we can is crucial in the fight against it. However, some sectors, such as the chemical industry, face challenges in transitioning away from fossil fuels, and renewable hydrocarbons are required to power them sustainably. Energy storage and transportation are also significant contributors to CO2 emissions, and we need renewable hydrocarbons to power them sustainably. Our DAC technology allows us to capture CO2 from the air at low-energy rates and produce green hydrocarbons, providing a renewable and sustainable source of energy. This makes it a critical part of the circular carbon economy.

Where do you currently stand?

F. Hildebrand: We have made significant progress since our inception. We have assembled a team of 15 highly skilled scientists and experienced engineers who are working tirelessly to develop our technology. We have built a prototype that captures a few grams of CO2 per hour to validate our process end-to-end, which was a significant milestone for us. Our technology has also been patented, and we have raised €3.5 million pre-seed financing to fund our growth. We are currently developing an industrial demonstrator, Greenberry 2, which will have a capacity of 100 t CO2 per year. We aim to complete this machine by September 2023, and it will allow us to demonstrate the effectiveness and scalability of our technology.

What‘s next for you?

F. Hildebrand: Our goal is to make our DAC technology widely available and to have a significant impact on reducing CO2 emissions globally. We are starting sales activities and will be open to receiving the first limited orders for Greenberry 2. Our technology is highly adaptable and versatile, which makes it suitable for various industries, especially chemicals. We also plan to continue our research and development efforts to improve our technology, for example, through enhancements of our absorber chemistry and make it more efficient and cost-effective.

What inspired you to launch the company?

F. Hildebrand: After selling the majority of my shares in my previous venture, Qualifyze, I wanted to tackle the challenge of climate change. I scouted German universities for people and climate-related technologies that could change the world. After countless meetings, I finally met Peter, the inventor of our DAC technology. Peter‘s work on atmospheric chemistry and carbon capturing built the foundation for our company. We soon realized that we needed a third person that could build the bridge between business and science, and that‘s where Niklas came in. His entrepreneurial and engineering background and his passion for climate tech made him the ideal addition to our team. Together, we are committed to making a difference in the world and contributing to a sustainable future.

There are a lot of DAC companies out there, what makes you believe that you can offer something new to the market?

F. Hildebrand: While there are many DAC companies out there, none have reached significant scale yet. Our approach is different because it needs very low energy and produces hydrogen as a byproduct. Additionally, we not only have overall low OPEX but also focus on keeping CAPEX low by utilizing as many low-cost components as possible and using off-the-shelf parts to increase scaling speed. We believe that CAPEX is underestimated by many companies, and our approach addresses this issue.

How can the CHEManager community help you?

F. Hildebrand: We are looking for pilot customers for power-to-chemical applications. Additionally, one of our big focuses for the future is the continued development of our chemistry, so partnerships with AI-driven chemical development companies would be very helpful. We believe that the CHEManager community has the potential to help us connect with the right people to make these goals a reality.

⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔

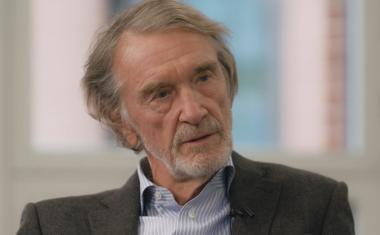

Personal Profile

Florian Hildebrand is an accomplished entrepreneur with a background in mechanical engineering. He has spent over five years working in the consulting, steel, and automotive industries. In 2018, Florian co-founded Qualifyze, a digital audit company that helps businesses ensure compliance with quality management standards. During his time Qualifyze grew to over 100 employees and gained a reputation as a leading provider of digital auditing solutions. In 2023, he co-founded Greenlyte Carbon Technologies, which he leads as CEO today.

⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔⇔

Business Idea

Low-Energy, Modular DAC Approach

Greenlyte Carbon Technologies has developed a breakthrough direct air capture (DAC) technology that extracts CO2 from ambient air and converts it into green hydrocarbons. The technology has several core advantages over other carbon capture methods.

First, it is highly efficient, utilizing low-cost components and operating at low temperatures close to the thermodynamic optimum. This means that it is cost-effective and sustainable, as it requires low energy rates to capture CO2.

Second, the technology has dynamic scalability, which means that it can adjust to fluctuating renewable energy sources. This is because the process is decoupled, which enables it to utilize available low-caloric waste heat. This feature allows Greenlyte‘s technology to be an ideal solution for various sectors such as the chemical industry, energy storage, and transportation.

Finally, Greenlyte‘s DAC technology has the added benefit of producing hydrogen in parallel with CO2 capture. The production of hydrogen can occur as part of the desorption process, allowing for direct mechanization. This is a significant advantage over other technologies as it provides a renewable and sustainable source of energy, which is essential for the circular carbon economy.

Modular System Ready for Fast Scale-up

Greenlyte is planning to start accepting pre-orders for its technology soon in the form of modular containers that capture and supply up to 10 kg of CO2 per hour.

The technology is based on 15 years of research at the University of Essen and has been well understood through over 25 research papers. Greenlyte’s strategy for scaling up involves using readily available and affordable components to construct their process quickly and efficiently. We focus on both low OPEX and CAPEX to achieve a CO2 price point of less than $100 per ton in the future. These values are reflected in the company’s daily decision-making processes.

Elevator Pitch

Low-Cost, Robust DAC Solution

Greenlyte Carbon Technologies has developed a revolutionary direct air capture (DAC) technology that extracts CO2 from ambient air and converts it into green hydrocarbons — price competitive with fossil fuels. The technology is highly efficient, cost-effective, and sustainable, utilizing low-cost components and operating at low temperatures close to the thermodynamic optimum. It has dynamic scalability, allowing it to run on renewable electric energy only.

Milestones

- 2022

- GCT was founded with a pre-seed round of €3.5 million, allowing the company to begin developing its innovative direct air capture (DAC) technology at full speed.

- The company acquired the intellectual property for its technology and began building a continuous lap prototype to validate the technology end-to-end.

- At the end of 2022, Greenlyte‘s DAC technology reached a technology readiness level (TRL) of 4.

Roadmap

- 2024

- By 2024, Greenlyte plans to build its first DAC unit in a commercial setting

- The company plans to receive approval for its first non-dilutive grant consortium and plans to raise a seed round

- With the funds, the company plans to reach technology readiness level (TRL) 6

- 2026

- By 2026, Greenlyte will focus on scaling its production, sales, and research and development efforts

- The company will be building an integrated kilo-ton carbon capture and utilization (CCU) unit in an industrial setting

- The company plans to reach tech