Quality and Safety in Biopharmaceutical Production

The biopharmaceutical industry is experiencing a drive towards biologic products due to their promise as treatments for chronic diseases.

This is reflected in the biologics market, which was valued at $382 billion in 2022 and is expected to grow rapidly with a compound annual growth rate (CAGR) of 9.1% to reach $893 billion by 2032.

Due to their sensitivity, biologic products can degrade or lose their activity when passing through the harsh conditions of the gastrointestinal system if administered orally. As such, most biologics are formulated to be administered by direct injection into the body. To ensure safety and quality, biologics must therefore be sterile.

Good manufacturing practice (GMP) regulations define product standards through strict regulations, which become even more stringent when dealing with sterile materials. Biologic products must be formed aseptically or terminally sterilized for quality and safety purposes.

“The GMP guidelines set out strict rules

spanning all components of production.”

The GMP guidelines set out strict rules spanning all components of production, from materials and equipment used, to cleaning techniques and validation. Recently, as a result of the advances in technology used for aseptic processing, Annex 1 of the GMP guidelines has been revised, re-evaluating how the biopharma industry approaches sterile manufacture. The modifications brought about by Annex 1 revisions aim to guarantee that product quality is built into the production process while ensuring staff safety through efficient training, risk assessments and procedures.

Overcoming Quality and Safety Challenges

Biologic manufacturing is complex, comprising several different processes and transfers throughout production. Incorporating sterility into manufacture adds further complication, with additional considerations required to protect the material from potential contamination. The presence of any contaminants in a sample — from environmental particulates to bioburden — poses a significant risk to the recipient. A significant risk occurs when transferring a product between subsequent stages of production, with exposure to the outside environment much more likely. Cross-contamination risk can still be present despite the use of validated cleaning procedures.

Numerous stringent regulatory requirements must be adhered to when producing a drug for human use as defined by the GMP guidelines. These regulations ensure that all products meet the required quality and safety standards, and that manufacturing remains consistent between batches. Revision of GMP guidelines assures that the highest possible standards are maintained, as is the case for the newly modified Annex 1.

Annex 1 Dictates Quality and Safety

Quality risk management (QRM) is embedded throughout Annex 1 to significantly reduce the risk of microbial and particulate contamination in the final product. Enforced from August 2023, changes to Annex 1 demand a manufacturer’s pharmaceutical quality system (PQS) to be integrated into production, outlining effective risk management strategy steps — to reduce contamination risks to personnel — as well as equipment and procedure training to build quality into the process.

In addition, a contamination control strategy (CCS) must be introduced for every sterile processing line. This living document should be continuously revised to identify any potential vulnerabilities throughout manufacture where containment breaches may occur. The risk will then be minimized through the introduction of preventative measures.

Revision of Annex 1 aims to decrease microbial and particulate contamination risks within a batch. Single-use technology (SUT) is one strategy to reduce exposure and contamination risks. Although associated risks to integrity of products such as extractables and leachables must be addressed as part of the CCS, using SUT can be an effective way of instilling sterility.

Leveraging SUT for Quality and Safety

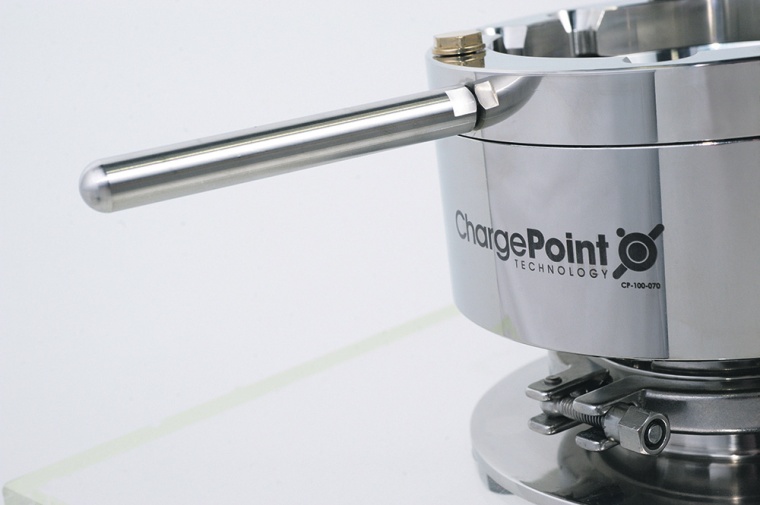

With the largest risk to sterility in aseptic processing occurring during product transfer between processing lines or equipment, the biopharmaceutical industry is harnessing SUT such as split butterfly valves (SBVs) and chargebags. SUT forms a barrier between the product and the outside environment and can be used to store, transfer and handle products without exposure, significantly reducing the risk of contamination.

SBVs are used to seamlessly transfer powdered materials throughout the production line. Resulting in a closed filling line, SBVs significantly reduce the risk of exposure during product transfer. When they are harnessed in combination with chargebags, the product can be stored or packaged in the container until it is needed for subsequent processing steps.

These SUTs can be integrated into current operations and help manufacturers meet the sterility requirements defined by Annex 1, significantly minimizing exposure and contamination risks to meet safety regulations. Quality assurance is also built into the process, removing the need for cleaning methods or validation when using SUTs. Each piece is replaced after use, which significantly reduces the risk of cross-contamination or bioburden within a drug compound.

“Revision of GMP Annex 1 aims to decrease microbial

and particulate contamination risks

within a batch.”

As demand for biologics continues to increase, changes in manufacturing capacity will follow. Traditionally used for small batch manufacturing, SUT will continue to evolve, increasing its ability to handle larger drug product capacities. Customer-driven innovation in the SUT space is transforming the sector. By harnessing SUTs’ flexibility, tailored solutions can be formed, meeting the needs of the customer and addressing changing demands in the biopharmaceutical industry.

Biomanufacturing Needs Quality by Design

Manufacturing drug products that meet defined safety and quality standards is essential. As the industry adapts to the revised GMP Annex 1, a quality-by-design methodology for sterile products is being built into aseptic processing.

To further mitigate contamination and exposure risks, the industry is moving towards SUT. These flexible systems protect drug products from the outside environment, allowing for effective product storage and transfer between processing lines, and integrating sterility into manufacture.

”Manufacturing drug products that meet defined safety

and quality standards is essential.”

A specialist supplier that has expertise in providing high-performance SUTs can aid in navigating the changing regulatory landscape, tailoring single-use systems to meet manufacturing and customer needs.

Author: Ben Wylie, Head of Product Management, Chargepoint

Technology Ltd, Liverpool, UK

_________________________

References

- Biologics Market Economic Growth CAGR of 9.1%, Restraints, Mergers and Forecast (2022-2032). GlobeNewswire News Room. [Accessed July 18, 2023]. https://www.globenewswire.com/en/news-release/2023/03/06/2620668/0/en/Biologics-Market-Economic-Growth-CAGR-of-9-1-Restraints-Mergers-And-Forecast-2022-2032.html.

- EU GMP Annex 1 Revision: Manufacture of Sterile Medicinal Products - ECA Academy. [Accessed July 18, 2023]. https://www.gmp-compliance.org/guidelines/gmp-guideline/eu-gmp-annex-1-revision-manufacture-of-sterile-medicinal-products-draft.