Reach: Warning Signs for Downstream Users and Strategic Responses

07.09.2011 -

Moving Target - Reach implementation is now in full swing, as the 2010 registration results are about to be communicated down supply chains and new processes for the most hazardous chemicals are progressively taking effect. Obtaining registration numbers for chemicals is not the end of the road to compliance and continued business in the European Economic Area (EEA).

Tim Becker from regulatory consultancy ReachLaw looks at the risks due to Reach in supply chains and their management as part of an overall compliance program.

Looking back, the agenda in 2010 for industry was rather clear, though demanding. Manufacturers and importers to EEA had to Reach-register existing ("phase-in") high volume substances exceeding 1,000 tons per year as well as certain very toxic substances of lower quantity by Nov. 3, 2010 with the European Chemicals Agency (ECHA) in Helsinki; in addition, they had to re-classify and re-label hazardous substances placed on the EEA market according to the new EU CLP Regulation by Dec. 1, 2010 and had to notify ECHA of it by Jan. 3, 2011.

From 2011 onwards, the situation is much more complex as a number of new duties arise under Reach, especially for downstream users (DU) of hazardous substances. DUs are in a delicate position, as they cannot register in this capacity, but depend on the upstream manufacturer or importer to supply duly registered substances covering their actual uses.

Otherwise DUs may have to take further action with a considerable impact on their business. Hence, risks due to Reach in supply chains are primarily occurring on the sourcing side.

What Are the Risks?

Legally, downstream actors may become themselves non-compliant because of insufficient action upstream. For example, if a formulator sells a mixture including a substance that hasn't been duly registered by his supplier, they may be in breach of Reach article 5 "no data, no market" and be subject to penalties under national laws.

Further liabilities can be triggered based on contracts with customers or under product liability aspects. Non-compliance becoming public may also have serious repercussions on a company's reputation and business.

Apart from this, the main business risk pertains to the future non-availability of certain substances due to (too) burdensome registration or authorization requirements, resulting in changes of suppliers, costs, raw materials or own products.

Looking Out for Warning Signs

A number of warning signs can be identified that put the DU's own Reach compliance or future supply of chemicals to him at risk. They may relate to the chemical, the supplier or shortcomings of the registration.

Future availability of the chemical is particularly at stake if it is or contains a substance of very high concern (SVHC) included in the authorization list (Reach Annex XIV). Authorization is a complex and lengthy process aiming at eventual substitution of SVHC with safer alternatives.

SVHC may in principle no longer be used after the so-called sunset date specified in Annex XIV, unless a successful application for authorization of continued use is submitted to ECHA by a defined latest application date. Annex XIV was filled with the first six substances in February 2011 and is expected to grow steadily over the coming years.

Another reason to be worried is a supplier being a relatively small manufacturer or importer who responds poorly to Reach enquiries. They may lack Reach awareness, a proper strategy and resources to complete the registration and - if required - authorization covering downstream uses. This may lead him eventually to discontinue the supply of the chemical following the expiry of the applicable registration deadline or authorization sunset date.

Furthermore, if the chemical originates from outside EEA, the DU may find himself in the Reach role of an importer with own registration obligations, unless the non-EEA manufacturer has appointed a competent only representative.

Similarly, if a trader has registered as an importer without being involved in the physical delivery of the chemical to EEA - and suitable contractual arrangements between the parties involved in the actual importation are not in place - there is a risk that the trader's importer status is not recognized by authorities, registrations are not valid and the "real" importer needs to register.

Importantly, DUs should not sit back only because they receive pre-registration or registration numbers for their raw materials from suppliers. Pre-registrations are only valid until the applicable registration deadline and frequently a later deadline has been mistakenly applied for toxic substances or due to incorrect volume calculation.

If the supplier has already registered a hazardous substance and provided the updated "extended" safety data sheet, the DU is obliged to check whether his uses are covered. If this is not the case, he has to take further action within tight deadlines. If the substance has only been registered as intermediate under strictly controlled conditions - a very frequent case - the DU may not use the substance outside these limitations.

How to Manage the Risks?

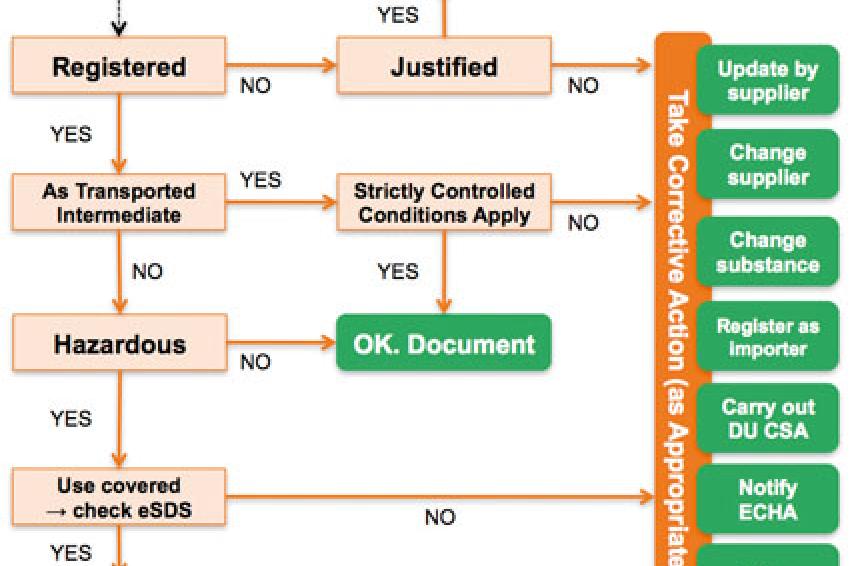

Based on a sound and up-to-date knowledge of Reach and its implications, chemical companies are advised to define and implement processes to manage identified risks as part of an overall compliance program. On the sourcing side, check lists and procurement procedures and taking into account the substance hazard profile and registration status are helpful tools to audit the suppliers' Reach compliance (fig. 1). In addition, appropriate clauses in purchase contracts should clarify Reach responsibilities and liabilities of the parties.

Good communication channels with suppliers, only representatives and customers are critical to ensure sufficient coverage of uses in registrations and to obtain any information requested by authorities rapidly. Furthermore, it is important that downstream actors understand their options to carry out certain compliance acts by themselves instead of relying on the upstream supplier (fig. 2).

DUs of hazardous chemicals should also make efforts to anticipate the substances which may end up on the Reach authorization list and decide if they want to continue using them. The Reach candidate list of SVHC for authorization with currently 53 substances and the registry of intentions on the ECHA website as well as the SIN list maintained by the NGO ChemSec including 378 substances fulfilling SVHC criteria may serve as early warning systems in this regard.

Conclusion

Detecting warning signs for non-compliance or future non-availability of substances in supply chains and setting up suitable processes to respond to these are pivotal for effective risk management under Reach. Companies have to invest significant resources and efforts continuously to meet this challenge, but will eventually be rewarded with a competitive edge through compliance.

Contact

ReachLaw

Keilaranta 15

02150 Espoo

Finland

+358 50 5871640