Solving the Riddle of Supply Chain Visibility

Which Benefits Result of More Visibility? The Views Greatly Differ

When it comes to what this additional knowledge consists of, what the resulting benefits are or how to implement it, the views greatly differ. This disparate understanding results from the fact that the added value of visibility does not lie in itself, but in what is gained from it.

The question is: What can a pharmaceutical wholesaler gain out of the temperature information of active ingredients on the way from the contract manufacturing organization (CMO) to the product producer? Or what does a pharmaceutical producer require an ETA (estimated time of arrival) of last-mile deliveries for? SCV has a different meaning for everyone, and the benefits depend on the use case.

Diverse Use Cases, Diverse Benefits

Even within the pharmaceutical industry, visibility can have different manifestations depending on the stakeholder, process stage or field of application. The distinction lies in the challenges and how SCV helps to manage those. Here, visibility can support many aspects from general processes, like sourcing, production, or distribution, up to specialized procedures, like the transport of living cells for cell & gene therapies.

A common challenge in the pharmaceutical industry, for example, is temperature management. Monitoring and tracking of temperature today are still mostly done with data loggers. They are read out at check points without having temperature visibility between the check points. Obtaining temperature visibility itself is not an added value. The actual benefit is rather provided by an alert indicating a critical point in a product’s stability budget, a resulting recommendation for a cooling system on the next transportation mode, and the provision of handling instructions to the receiving party.

Another example: Information about the shortage of a certain product in the warehouse is already too late for the pharma retailer, because at this point, no intervention is possible anymore. Once incidents on regular sourcing routes occur, the purpose of visibility is to inform about this, give alerts for directly affected objects, indicate indirectly or upcoming affected objects and provide alternatives, like re-routing or prioritization options.

What all stakeholders in these examples have in common is that they have to focus on high product quality under the tight restrictions and regulations of the pharma industry. So even though the appearance of SCV is distinct, it supports the essential goals in all scenarios.

„Before starting a visibility project,

it is important to create a clear vision.”

Creating a Visibility Vision

Before starting a visibility project, it is important to create a clear vision. Although this advice is widely known, it is all too often not heeded. A visibility vision defines concrete goals which will act as a framework for the future supply chain, whereas these goals can describe visibility benefits in an isolated process section, such as physical shipments, or the supporting role in cross-enterprise processes, such as order-to-cash. The following guidelines can be helpful when creating a visibility vision:

- Visibility should help me to manage my supply chain better.

- I can only manage what I can see.

- Therefore, I have to define what I want to control and what I need to see for that.

A vision should be created independently of constraints or technical solutions and focus solely on the achievement of benefits. Specific use cases as well as the description of possible intervention options are particularly suitable to identify and describe those.

“I can only manage what I can see.”

Asking the Right Questions

When developing a visibility vision, it is critical to ask the right questions and to question the right things. Referring to the suggested guiding principles, it is therefore necessary to shed light on “What” is to be managed by SCV, and “How” this can be done. However, the most important question, the “Why”, must be asked first. Often the trigger for more visibility is not the direct desire for more information, but challenges like recurring delays, states of constant firefighting or dissatisfied customers.

Based on the answers to the why, how and what, the decisive factors for visibility in a supply chain can be distinguished. These may include areas such as system landscapes and architectures, data structures, business partners and internal stakeholders, fields of application or process sections and their objects as well as their linkage with other process sections or objects. Putting together the different elaborated visibility requirements will result in the future end-to-end supply chain visibility vision.

A Use Case

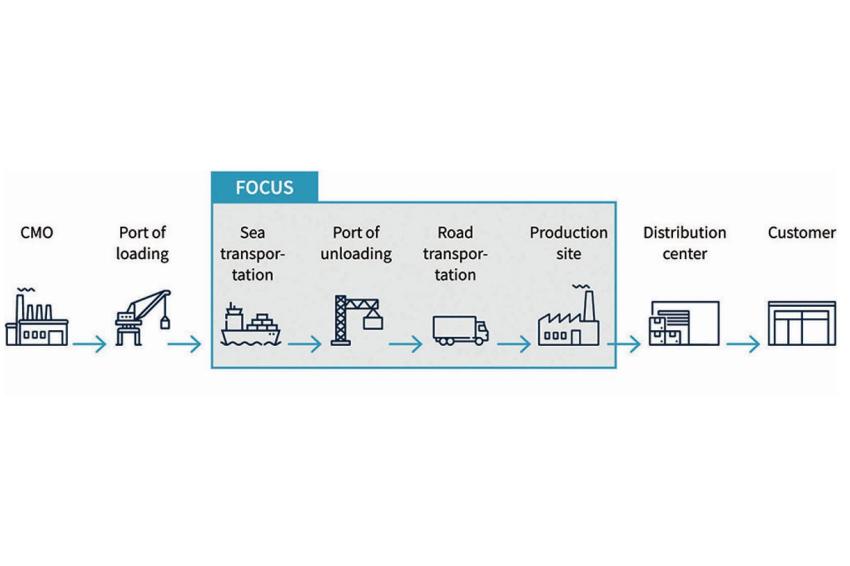

The following use case will illustrate this: A pharmaceutical producer procures a major part of the raw materials and active ingredients via the port of Rotterdam, from where they are transported by truck to the production facility. Currently, the port informs the producer when the goods are ready for pick up whereupon he informs his road forwarders to pick up the goods at the port. With its high focus on the port of Rotterdam, the producer aims for more SCV in this process section.

“Why” Does He Require more Visibility?

One reason for gaining more visibility is that the producer aims to execute the inbound transport from the port to the production site less manually. This results in more cost-efficient processes and less susceptibility to errors. A different focus is on increased production planning reliability, whereby a reduced safety stock still goes along with a resilient supply chain.

So “How” Can these Goals Be Achieved?

First, by using a direct information access, through which the freight forwarder will be informed about arrived goods without any detour. By a timeslot booking the forwarder informs the producer about the planned arrival date at the plant. Second, during the sea transport, planned and actual events (e.g., calling different ports) are matched or an ETA is calculated. Alerts about significant discrepancies will be given early enough to identify alternative sourcing options.

“What” Value Creates each Type of Visibility?

In the first case, vessels are tracked via an integrated visibility provider with direct distribution of the information to the carriers via a collaboration platform. Further integration of information at the producer is not necessary. In the second case, a dashboard provides a status overview of all orders on vessels. The provision of an ETA by a visibility provider is an option here, but it is even more important to draw conclusions about affected orders from the vessel data to integrate this information into further planning. This way the producer can see the effects of delays directly in relation to his production forecasts.

The example clearly shows that answering the “why” is the driving force in implementing the right solution for visibility.

From Strategy to Implementation

Creating a detailed vision allows to define clear goals, but also to involve and convince other stakeholders before the selection and realization of a technical solution starts. As for visibility solutions, there is a wide range of mature providers and solutions on the market, be it hardware, software or services, serving common visibility needs as well as special niche requirements. The implementation approach can differ from a fully integrated architecture (within an existing landscape) to a plug-and-play software installation.

For vision definition and implementation, a modular use-case based approach is recommended. The gained improvement effects can be made visible quickly, which leads to a didactical learning process. The incremental evolution makes it important to always keep the overall vision in mind. In case of deviations between requirements and vision, the vision needs to be adjusted first.

First steps to supply chain visibility can be done right away. Ask your operational teams today for their visibility needs and understand their requirements and from that point form a vision for creating an effective solution.

Authors: Constantin Reuter, Principal, Camelot Management Consultants, Basel, Switzerland;

Nina Eckenbach, Senior Consultant, Camelot Management Consultants, Cologne, Germany