Sumitomo Scales Up Ethanol-to-Propylene Process

Sumitomo Chemical has constructed and begun operation of a pilot facility at the Sodegaura site of its Chiba Works for its new proprietary process to produce propylene directly from ethanol.

This new technology is expected to significantly contribute to the petrochemical industry’s effort to switch to alternative feedstocks, and is supported by the New Energy and Industrial Technology Development Organization (NEDO) Green Innovation Fund. The Company will accelerate its demonstration project for this process, with the aim of commercializing this process and licensing the technology to other companies by the early 2030s.

Propylene is a widely used key chemical, and currently, in Japan, it is mainly produced from naphtha, a fossil resource. Ethanol, on the other hand, can be produced from biomass such as sugarcane, corn, and non-edible materials like pulp. In recent years, there has also been substantial progress in the development of technology to enable the large-scale production of ethanol from combustible waste, and its industrialization is in sight. As the shift toward sustainable essential chemical feedstocks advances, ethanol is increasingly expected to serve as an alternative feedstock that replaces fossil resource-derived chemicals.

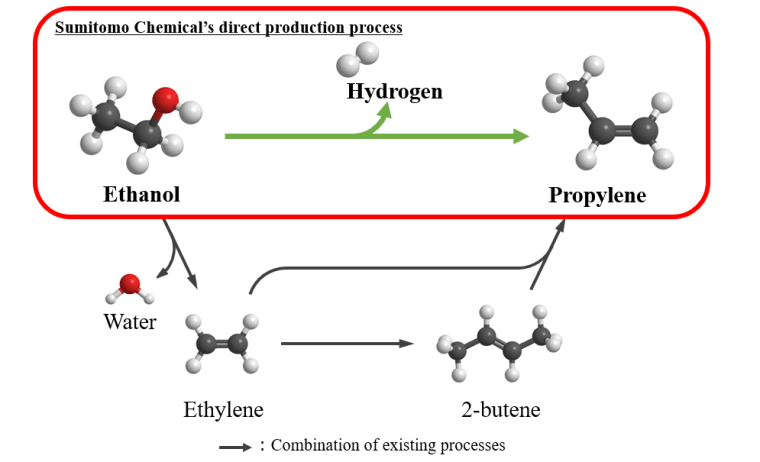

Sumitomo Chemical’s newly developed process enables the direct production of propylene from ethanol. Unlike other propylene production processes using ethanol, this process allows for the one-step production of the final product propylene without passing through intermediates such as ethylene. Because of this distinguishing feature, the process is anticipated to reduce production costs. Moreover, it also generates hydrogen as a by-product. This is another advantage, because when bioethanol is used as a feedstock, it allows for the co-production of bio-derived hydrogen.

The company will work to acquire the various data necessary for industrialization of this process, while also conducting extensive marketing activities for polypropylene produced from propylene obtained through this process. The Company aims to commercialize and license this technology by the early 2030s.

Sumitomo Chemical is significantly changing the direction of its petrochemical-related businesses, steering them toward value creation through technologies that reduce environmental impact. The Company is advancing structural reforms both in and outside of Japan, while at the same time, stepping up its technology licensing and catalyst sales, including for this process. Sumitomo Chemical also aims to establish green transformation (GX) solutions business as a new business model it pursues beyond 2030, in which it will build a circular resource value chain involving raw material suppliers and product brand owners, as well as monetize the CO2 reduction achieved by customers.