Sustainable Chemicals from Renewable Raw Materials

16.03.2021 - Innovative Technology Enables Advantageous Oleochemistry Products

The Kanzler Verfahrenstechnik group (KVT) has been engaged in the production of high-quality glycerin grades at Glaconchemie for 15 years and in the technology of residue-free production of epichlorohydrin via glycerin for 10 years. Currently, the largest plant for the production of glycerin-based ketals and formals is being commissioned at the subsidiary company Alteqo (a 50% joint venture of KVT and Chemcom) while developing a new generation of plasticizers.

Oleochemistry represents the area of industrial chemistry in which natural oils and fats are used as raw materials. This has attracted great interest in recent years, as some of the products it supplies have preferable properties and comparable performances to conventional products. In addition, these are safer and more sustainable chemicals through which health and environmental challenges of fossil feedstocks can be addressed. In the past, complicated manufacturing processes and the lack of mature technologies have hindered the success of this industry. But recently, thanks to new innovative technologies, more and more petrochemical products have been replaced by products of biological/organic origin, which neither have toxic properties nor pose a threat to the environment.

Since 2004, KVT‘s Oleochemicals division has been dedicated to the production of sustainable chemicals from renewable raw materials. In addition to economic aspects, the focus in technology development is primarily on closing the cycle and avoiding negative environmental impacts. Driven by the glycerin market expansion caused by the first biodiesel wave, KVT‘s subsidiary Glaconchemie in Merseburg produces glycerin of the highest quality used in applications varying from toothpaste to skin care and from pharmaceuticals to confectionery production.

These purely vegetable non-GMO glycerin feedstocks are increasingly being overtaken in Europe by glycerin coming from biodiesel production using used cooking oils (UCO) and are therefore only suitable for technical applications.

Glycerin Replaces Propylene in the Production of Epichlorohydrin

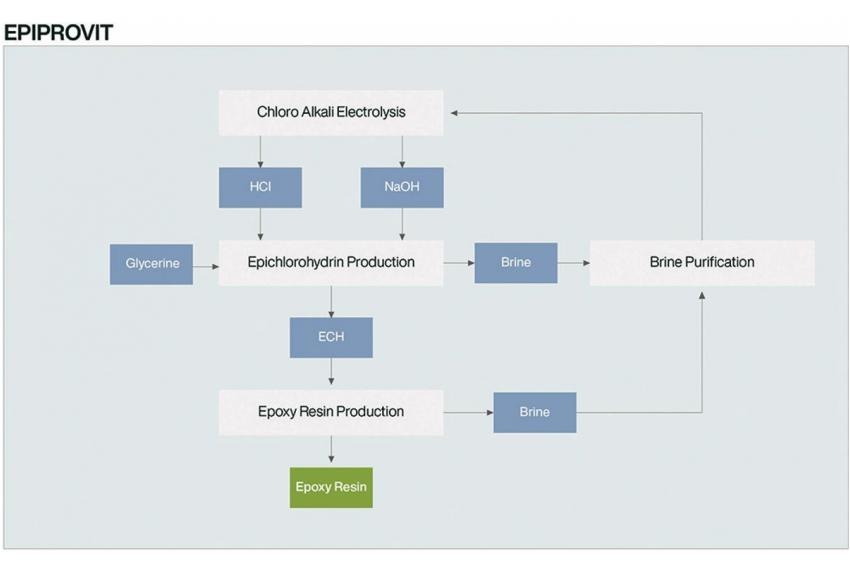

The availability of low-cost glycerin from UCO and palm oil processing has made it permanently more economical to use as a feedstock for epichlorohydrin production than propylene. However, the production of Epichlorohydrin via glycerin did not really increase until the Chinese environmental legislation prohibited to discharge wastewater from the propylene process. KVT‘s Epiprovit process, with its integrated process for high-pressure oxidation of the brine from saponification, allows to reduce the amount of brine by 90% on the one hand and to purify it so efficiently (99.9%) that the brine can be reused in chlor-alkali electrolysis plants as a raw material for the production of caustic soda and chlorine.

The value of the recovered brine fully covers the costs incurred by the brine purification plant. Originally, this process was developed to clean the contaminated wastewater from epichlorohydrin production, which is toxic to biological wastewater treatment plants. In recent years it has been shown that the technology is also suitable for the purification of other wastewaters such as those from the production of epoxy resin or propylene oxide. Usually, the contaminated brine contains salt in high concentrations and organic contaminants such as hydrocarbons, oxygen, nitrogen, and chlorinated compounds. The purified brine can be recycled for reuse in other processes.

This brine purification process is currently in operation or being implemented for epichlorohydrin productions with a total capacity of about 700,000 t/y worldwide and provides recovery of about 550,000 tons of sodium chloride/ year. In sum, this technology is the best example that environmentally friendly processes can indeed be economical and how important it is to promote the efficient use and recovery of resources.

Ketals and Formals from Glycerine Provide Interesting Solvent Properties

Solketal, commonly known as isopropylidene glycerol, has been popular for decades as an odorless and skin-compatible solvent and solubilizer between polar and nonpolar liquids. So far however, it has not been easy to find on the market and it has not yet received the proper attention that it deserves.

KVT’s 50% JV with Chemcom, Alteqo, in Farmsum, Netherlands, produces up to 20,000 t/ y of „Glycasol“ (Solketal), which is used as a solvent for biogenic active ingredients, odorants, cleaning agents, antioxidants, and is also used in cosmetic products. Glycamal (glycerinformal) is also produced in a similar manufacturing process and is used in veterinary medicine drugs, as a solvent and building block for exciting syntheses.

Plasticizers Can also Serve Environmental Protection

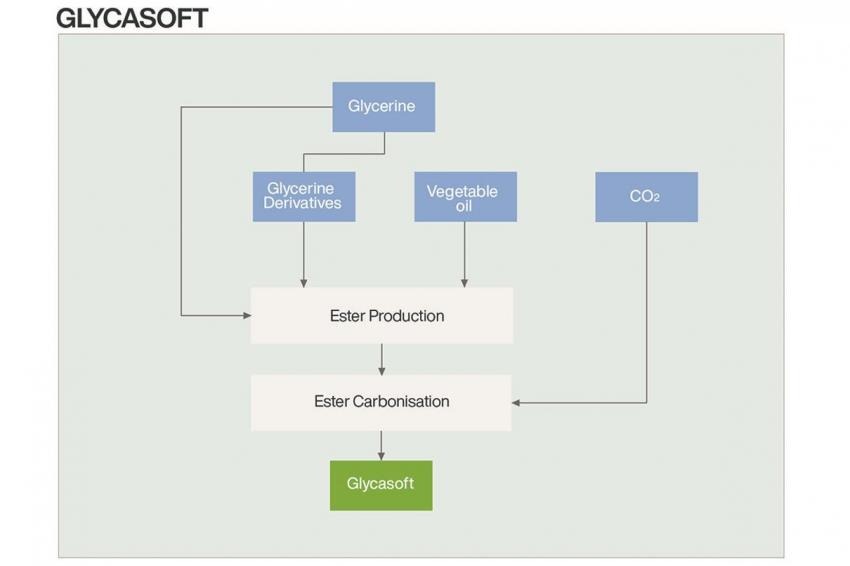

The new plasticizer Glycasoft is based on glycerin derivatives, vegetable oil and carbon dioxide. In the known applications, Glycasoft not only scores with its non-toxic features and its processability equal to that of the usual phthalates, but even surpasses them in essential properties such as temperature resistance and migration behavior.

The incorporation of carbon dioxide into the molecular structure not only improves the properties of the plasticizer, but also contributes to the reduction of greenhouse gases. Thus, Greta Thunberg will also be pleased with it.

The mission of our industrial group is to develop technologies and manufacture essential chemical products with a conscious choice of renewable raw materials and closed-loop concepts.

Author: Walter Kanzler and Florian Kanzler, Managing Directors, Kanzler Verfahrenstechnik, Graz, Austria