Transition Pathways toward CO2 Neutrality

Chemical parks are locations of intensive value creation. They are a driver for sustainable development with a high economic, ecological and social impact.

Major current challenges – short-term: implications of the war in Ukraine, mid-term: energy independency from Russia, and long-term: CO2-neutrality by 2045/2050 – all come together in chemical parks. But how do park operators handle these challenges? What initiatives are pursued to increase competitiveness and foster sustainable development in chemical parks across the globe?

These questions were the topic of a panel discussion with Joachim Kreysing, COO of Infraserv Höchst (Frankfurt, Germany); Tan Cheng Guan, Executive Vice President, Group CEO’s office, Sembcorp Industries (Singapore); Martin Naundorf, Head of Sales and Business Development, InfraLeuna (Leuna, Germany); and Wouter Demenint, Commercial Manager Delta Corridor Project, Port of Rotterdam. The following text summarizes key results of the discussion, which was chaired by one of the authors, Hannes Utikal.

Chemical Parks: Focal Points of Current Management Challenges

Chemical parks exist all over the world in order to create value by process engineering. The majority of these industrial sites depends heavily on fossil energy and raw materials for production. One major concern of industrial parks in 2022 is the question on how to handle the current energy crisis with the high and very volatile prices for natural gas and electricity. In Europe, one major additional challenge is the pure availability of natural gas. Finding immediate substitutes for natural gas was named as the major challenge for chemical parks.

“Chemical parks are locations

of intensive value creation.”

Light oil was seen as a substitute for gas with regards to the generation of heat. Industrial park operators described operational flexibility as not fully gradual – at least 50 % of the current natural gas supply in Germany would be necessary to keep the production system running – less natural gas would lead to a stop of the industrial production. The current energy crisis puts, thus, even more emphasis on the necessity to accelerate the transition to a fossil-free chemical production.

Transition Pathways are Site Specific

The development of a transition pathway starts with an analysis of the current resources and energy concept of a site. Local value chains and climate strategies of the producers on site need to be analyzed. One main challenge of a chemical site with multiple users such as the industrial parks in Frankfurt or Leuna is the regional coordination and alignment of the global climate strategies published by large global companies. Chemical parks need to translate companies’ global CO2 reduction targets to the regional context and they need to report a site’s regional carbon footprint to the local community. In chemical parks, global climate strategies meet regional requirements and reporting duties.

Role of Industrial Park Operators

Industrial park operators play a crucial role in co-developing a defossilization strategy with their major clients. Together, they develop and implement the transition pathway. As park operators typically manage energy and material flows in chemical parks, they have access to emission data of different production facilities. This forms the starting point for developing a transition pathway. Depending on the governance structure of the industrial park operator, its role may vary: In a single- or major-user site, the status quo analysis is easier as less legal entities are involved in comparison with a multiple-user site consisting of a variety of stakeholders with specific interests. A transition pathway is characterized by the timing of investment in low carbon technologies and the balancing of economic and environmental considerations. Publicly owned industrial parks may focus more on CO2 reduction targets and may need to focus less on the financial profitability of an investment than a privately owned industrial park. On the other hand, decision-making processes may take longer in publicly owned parks compared to privately owned entities.

Geographic and National Context

The development of a transition pathway is heavily influenced by the geographical location, namely the availability of fossil-free feedstock (e.g., biomass) and energy (solar, wind, water, geothermal) on site or in the area. In addition, the current regional infrastructure, the availability of pipelines, roads and the energy grid at the right dimension are crucial context factors. But the transition is not only a technical, it is a socio-technical endeavor: National context factors such as a nation’s institutional framework (e.g. national CO2 reduction strategies, subsidies for low-carbon technologies, reliability of regulatory developments) and a country’s position in technology and innovation (e.g., low-carbon technologies, R&D investment, openness for new technologies) and human capital (qualified personnel; available upskilling and reskilling training) influence the transition pathway, too.

“In chemical parks, global climate strategies

meet regional requirements

and reporting duties.”

In addition, megatrends like a renewable hydrogen economy are locally driven undertakings and show a much higher availability in hot spots as of today. And finally, developments in the field of global trade and investments, the competitiveness of one nation in comparison with another with regards to local production and consumption, have to be taken into account when developing a transition pathway. It was mentioned in the discussion, that energy prices in Germany would be seven to nine times higher than in the US in August 2022. It was assumed that higher energy prices may persist in Europe over the next years leading to a competitive disadvantage of Europe with regards to energy-intensive production. These macro-economic developments are context factors for the local actors, they can only partially be influenced by park management or local stakeholders.

Green Ecosystems are Crucial

While chemical parks are the focal points of the transition, with park management and the major local producers being in charge of investments in low-carbon technology and using fossil-free feedstocks, they cannot realize the transition on their own account. They are part of ecosystems, which encompass complementary companies such as providers of low-carbon technologies and finance, actors from academia, policy making/regulation and civil society as well. Those different actors need to work together in order to create an effective transition pathway with economic, ecological and social benefits. While some of the necessary actors are in the region of a chemical park, especially the links in the fields of innovation go beyond the region in which a chemical park is located.

The port of Rotterdam in the Netherlands can serve as one example on how a multi-stakeholder ecosystem may be developed and managed to ramp up a green hydrogen economy. The effectiveness of public-private collaboration was seen as one key success factor in the transition to a fossil-free economy. As some of the technologies for a fossil free chemical industry are not yet fully developed and regulatory aspects (e.g., in the field of carbon capture and storage, CCS) are not yet clarified, a continuous public discourse on the requirements of a fossil-free chemical industry is needed to secure public acceptance of new technologies.

Case Study: Process4Sustainability Cluster

In 2021, the cluster “Process4Sustainability: Cluster for climate-neutral process industries in Hesse” was founded in Frankfurt. It is funded by local companies, and the state of Hesse and the European Union alike, and managed by the Center for Industry and Sustainability at Provadis University of Applied Sciences. In addition to site operator Infraserv Höchst, the project's supporters include Sanofi, Clariant, Celanese, Kuraray and Bayer.

Goal of the cluster is to support companies in developing and implementing transition pathways toward CO2 neutrality by 2045 at latest. In this context, suitable technical solutions for reducing CO2 emissions are analyzed and opportunities for green growth are explored.

Key Levers to CO2 Neutrality

The industrial park Frankfurt sees itself as an innovation campus, where low-carbon technologies can be tested and scaled up in an industrial setting.

The project partners decide together about joint work packages and joint focal points. A first step was to identify the carbon footprint of the industrial park Höchst encompassing the production activities of all companies on site. The energy- and raw material-related CO2 emissions were analyzed (over all three relevant scopes). The result: direct CO2 emissions associated with energy production account for only one third of the total CO2 emissions; roughly two-thirds of the emissions are associated with the fossil resources used in chemical production.

Together with the Society for Chemical Engineering and Biotechnology (Dechema), various transition pathways were analyzed for the industrial park. These include, to different degrees, the use of non-fossil raw materials (e.g., biomass), the use of green hydrogen, the use of green electricity, the electrification of heat and the use of CO2 as a raw material in chemical production.

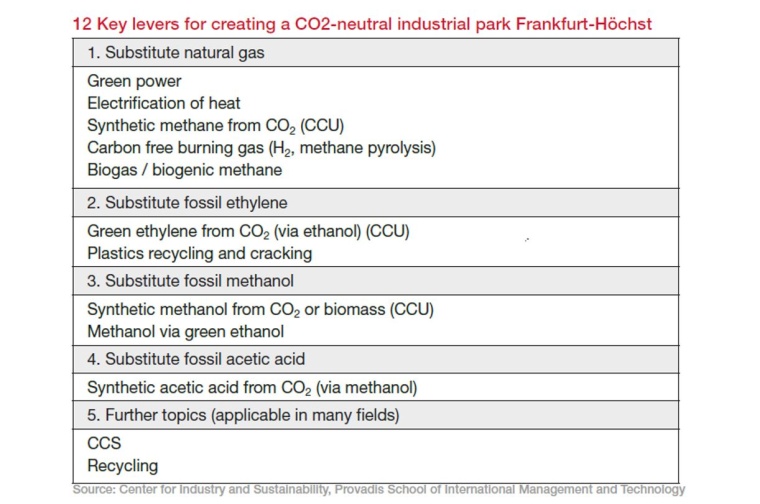

In a large number of expert discussions, 12 technological levers for CO2 neutrality were identified (see table), which are now being examined in more detail together with innovation partners. Not every relevant technology embodies solution to the same degree or scale.

The cluster Process4Sustainability seeks to partner up with relevant actors driving forward the transition toward a climate neutral process industry .

Authors: Hannes Utikal, Head of the Center for Industry and Sustainability, and Marcel Loewert, Business Development Manager, Center for Industry and Sustainability,

Provadis School of International Management and Technology, Frankfurt, Germany

______

“Transform the European Process Industries”

In May 2022, an international expert workshop on transforming the process industry in Europe was held with more than 70 experts from industry and academia. The presentations and additional material are available at:

https://bit.ly/Provadis-IPM2022

Company

Provadis School of International Management and Technology AGIndustriepark Höchst, Gebäude B 845

65926 Frankfurt

Germany

most read

VCI Welcomes US-EU Customs Deal

The German Chemical Industry Association (VCI) welcomes the fact that Ursula von der Leyen, President of the European Commission, and US President Donald Trump have averted the danger of a trade war for the time being.

Merck Acquires Chromatography Business from JSR Life Sciences

Merck to acquire the chromatography business of JSR Life Sciences, a leading provider of CDMO services, preclinical and translational clinical research, and bioprocessing solutions.

CHEManager International Media Kit 2026

Compelling solutions through strategic partnerships

Ratcliffe: Chemical Industry in Europe at a Tipping Point

Ineos CEO Ineos calls on European politicians to save the chemical industry.

BASF Sells Majority Stake in Coatings Business

BASF sells a majority stake in its coatings business to the investor Carlyle.