Using Digital Twins for Sustainable Manufacturing Processes

Sustainable manufacturing is one of the most common demands industries, such as the pharmaceutical, chemical, and biotechnological industries, are faced with today. Europe needs to become more resilient and establish new sustainable processes in industry utilizing new technologies, such as digital twins.

In the last few years, any circumstances taken for granted were wiggled or even turned upside down. We had to learn that in a globally connected world, the sun does not rise more beautifully every day. We learned that the supply chains were disrupted. Many comfortable conditions we could have enjoyed during the last decades, and we conceived as being on solid ground, have been turned upside down. Thus, Europe needs to become more resilient. On issues of healthcare and our core industries, on which Europe's prosperity rests. We need to be more adaptable to influences on the European economy, where we do not have a direct impact.

Resilience through innovative Sustainable Manufacturing Processes

For over 20 years, many pharmaceuticals have been produced outside of Europe due to cost and probably due to existing intellectual property rights. Furthermore, many pharmaceuticals are produced in a batch-wise manner. This led to a situation in Europe where some pharmaceuticals were not available for patients. During the Covid pandemic we, the Europeans, became aware of breaking supply chains, but we also learned that we are great innovators and able to invent safe vaccines within a noticeably short time if the pressure is great enough.

This learning curve shall be used as a springboard in the future to become better in healthcare industry, chemical industry and other industrial areas.

Setting the Course for Sustainable Innovations

Sustainable manufacturing is one of the most common demands industries, such as the pharmaceutical, chemical, and biotechnological industries, are faced with today.

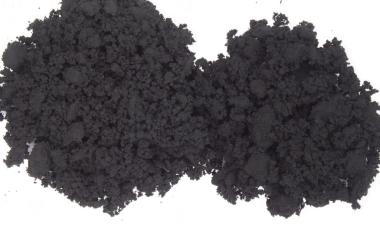

One of the most straightforward sustainable manufacturing utilizes mechanochemistry. An example of this is grinding with mortar and pistil - a mechanochemical treating method – which goes back to the stone age. Since then, in the last century, several mechanochemical methods and apparatus, such as specific ball mills were designed to increase the energy input into the grinding process, to initiate chemical reactions besides particle size reduction. Furthermore, extruder or plasma assisted processes were developed for batchwise or continuous processes are well understood and can be optimized for specific educts and products with reduced by-products.[1,2] Potentially, inflexible infrastructures and fixed distribution channels hinder the establishment of new sustainable processes and products.

So called “old technologies” may be converted as more sustainable processes with new innovative insights, if the existing infrastructure can be customized and new distribution models established. These innovations can be protected by intellectual property rights, such as patents, and be exploited by Europe’s industry.

For example, the first German patent (DE 1) discloses a “Process for the production of a red ultramarine dye”. The synthesis comprised of the following steps: Ultramarine violet is subjected to the action of vapours of a more or less concentrated nitric acid at 130 to 150°C. Highly concentrated nitric acid produces a colour rising to light pink; diluted nitric acid, on the other hand, produces a deep to darker red ultramarine. This “old process” was free from solvents and a part of it, together with current state of the art considerations, could be transferred into a new sustainable manufacturing process of other products. This example shall not present as a proposal to produce ultramarine dye, but represents an example for known processes that may be applied to different production examples. Therefore, the above-mentioned considerations can induce a mixed synergistic innovation process.

"Sustainable manufacturing is one of the most

common demands industries are faced with today."

Moreover, a very brief definition of mechanochemistry and sustainable manufacturing will be given below. Sustainable manufacturing defines a chemical process avoiding unnecessary compounds, hazard initial substances, hazardous products and solvents, saves energy, reduces the complexity of synthesis and may consider many more environmental principles for a sustainable conduct. Mechanochemistry is an old technique that utilizes the impact of mechanical forces to drive chemical reactions, often without added solvent or heat.

It is a fallacy to believe that to achieve these goals development of completely novel techniques is necessary. A holistic view is proposed, considering novel techniques, techniques used by nature, and sometimes old techniques in a new set-up with novel amendments and supplements that lead to sustainable manufacturing techniques in the classical pharmaceutical and chemical industry. An objective view and analysis of the whole set-up and a consequent holistic solution with a vast view into the future, is needed.

One key method to achieve this goal, is to continually question: “Is the sustainable behaviour of the past and present also a sustainable behaviour in the future or can it be improved?” Therefore, a current sustainable innovation may be replaced by a more sustainable innovation of tomorrow or sometimes a look in the past may also be useful for finding an old but environmentally friendly synthesis or product that may be amended and/or supplemented.

A good source for a classification of known industrial processes and products is patent literature. To enable the evaluation and classification of known industrial processes and products with respect to the criteria for sustainable manufacturing, the 12 basic principles of Green Chemistry, which were developed by Paul Anastas and John Warner in 1984, have to be observed.

Mechanochemistry, as well as gaseous reaction conditions in combination with the use of renewable energy, are therefore examples best suited to achieve most of these principles and are applicable to various reactions. A balanced and mixed IP strategy will also support the development, use and dissemination of greener chemistry with sustainable manufacturing, as patents protect the inventions of innovators over a period of time. They also drive further innovation by making the innovations public to the market companions, who may try to invent more improved novel developments.

In an objective way, factors that may hinder innovations should be considered. Some non-exhausting examples are the own subjective imagination of involved people, missing decisions of management or limited imagination of other participants, general framework conditions such as laws, regulations, directives and other guidelines, established infrastructure, rules of the market, cost etc. Important impediments for innovations are product policy aimed at product differentiation rather than product variation, that may dominate a company's innovation strategy. A corporate policy based on persistence, the commonly used “me-too-strategy”, waits until a third-party innovation has established itself on the market for example. This strategy relies on tradition out of conviction and hinders a switch to sustainable manufacturing and resilience.

As key-factors, the approved development costs and the available equipment frames innovations and inventors’ possibilities. In addition, today most developments require at least one or more cooperations with one or more market operators due to their complexity of the task. Therefore, there is a necessity of research collaborations with cooperation agreements and non-disclosure agreements that make a practiced, open, trusting, and cooperative collaboration of the participants possible. The assignment of rights to inventions must be proactively regulated in cooperation agreements, whereby national special legal regulations must be considered in international inventor teams.

Additionally, costs must be examined for securing the developments via intellectual property rights well before disclosing the invention to a third-party or a market launch. The cost for intellectual property shall not only be considered to secure the investment against third-party use, but also as a marketing tool to prove the innovative strength of a company.

The obstacles, which are not to be understood exhaustively, are only intended to indicate possible difficulties to be solved, resolved, or overcome after a kick-off meeting for technical developments by enthusiastic inventors with a great deal of optimism, persuasion, perseverance as well as technical, legal, and rhetorical knowledge.

Valid IP rights secure the innovator a monopoly position in the markets and thus enable them to recoup their investments and make profits. Likewise, IP rights give the innovator or pioneer protection against imitators, such as companies that are considered early followers and late followers, or against companies that want to market detailed improvements such as a modification. Valid IP rights are also marketing tools proving the innovative spirit of a company, e.g., in social media, and are an enormously important part of the value of companies.

Setting the course for Sustainable Innovations using Digital Twins

Digital Twins (DigiTwins), are a large research initiative in Europe and beyond, aimed at revolutionizing healthcare and biomedical research for the benefit of citizens and society. They are computer models enabling a prediction of optimized chemical processes in view of all issues to be considered in a chemical production process. Artificial intelligence (AI) and digital twins are well developed and allow processes to be designed in a fully virtual environment. Moreover, costs and by-products can be estimated and optimised before any investment in a new production line is necessary.

Testing modular standardized connectable, continuously operated, small sized extruders, gaseous reactors, or mechanochemical reactors, may allow a reduction of the plant size and a switch from batchwise production in the pharmaceutical industry to a continuous production as is typical for the chemical industry. Using digital twins for the estimation of a new process set-up, e.g., switching from solvent assisted batchwise production to a continuous extruder supported production, enables development of nearly fully automated production processes in small sized reaction plants in movable scalable infrastructures. Moreover, the calculations of the digital twin can lead to heavily reduced production costs.

Setting the Course for Intellectual Property (IP) Strategy for Sustainable Innovations

Enabled through the intensified cooperation of EU member states, the European legislator has established a more uniform and cost-effective patent system. This new system can be used from 1st June 2023 in participating member states of the EU through the Unified Patent System covering a Unitary Patent (UP) and Unitary Patent Court (UPC).

The "unitary effect" of the new Unitary Patent avoids the previous fragmented protection in European Union countries, as all EU member states, except Spain and Croatia want to implement the system in the future. The administrative and cost burden for all parties will be significantly reduced.

The current system at the European Patent Office (EPO) is based on a centralised examination system. If a European patent (bundle patent) is granted after its conclusion, it must be validated in the contracting states, in order to be able to develop its protection nationally as a bundle patent. For this purpose, parts or the entire patent must be translated into the national language or into English in various countries at considerable cost. In addition, there are national representative fees and, in some cases, official fees.

The unitary patent, on the other hand, is a European Patent with unitary effect, and must be translated completely into English for at least the first six years, if the text version is available in French or German. If it is available in English, it must be translated into another official language of the European Union. The new system now allows, with effect for the participating EU member states, to file a request for "unitary effect" with the EPO, within a time limit following the grant of the patent in the established central examination procedure.

However, the great advantage of the unitary patent, is the territorial, uniform extension of protection of the granted patent in currently up to 24 participating EU member states. Until ratification in all member states, there will be different generations of unitary patents with extensions of protection in the member states, with deposited instruments of ratification. Currently, about 17 member states, such as France, Italy, the Netherlands, Germany, and Denmark, have initiated or completed the ratification process. In all other contracting states of the European Patent Convention, the granted European patent can still be validated nationally. Alternatively, a patent applicant can take the purely national route by applying for a national patent and thus also wanting to ensure a purely national jurisdiction.

European legislator has set a legal framework with the Supplementary Protection Certificate (SPC) Manufacturing Waiver (Reg. 2019/933 amending Reg. No 469/2009) that allows the production of specific generic pharmaceuticals during a certain time of the patent term, allowing stockpiling for the export of generic products outside the European Union, without patent protection. This is in addition to the former possible research privilege and Bolar-Roche Exemption. These two legal frameworks will strengthen the resilience of availability of generics by reinstallation of the production of generic pharmaceuticals in Europe. As a side effect these frameworks will strengthen the resilience of Europe’s healthcare system and create safe jobs, especially when combined with sustainable manufacturing methods which are optionally designed by digital twins.

Setting the Course for Europe’s future

European institutions should foster natural science on all levels from school to work during the working lives of European citizens. They should check critically marketing costs that avoid real innovations, due to the above-mentioned obstacles. And importantly they should boot-up the implementation of innovative sustainable manufacturing.

Utilizing and promoting the above-mentioned tools by market players, public institutions, research institutions etc. within the new European legislative framework, an innovative transformation of Europe’s pharmaceutical industry and parts of chemical industry to a sustainable and resilient manufacturing is possible.

Author: Tanja Bendele, Founding Partner, Ruhr-IP Patent Attorneys, Essen, Germany

[1] Federio Cuccu et. Al, ChemSusChem 2022, 15 e202200362

[2] Robert R.A. Bolt et al., Chem. Soc Rev., 2022, 51, 4243-4260

Tanja Bendele is founding partner of Ruhr-IP Patent Attorneys in office partnership. She is head of the department of chemistry and pharmaceuticals including life sciences, medical technology, 3D technology and process engineering, represents international corporations as well as medium-sized companies. She holds a doctorate in chemistry and is a German and European Patent Attorney. Furthermore, she is studying electrical engineering and information technology. She is a member of the board of the German Chamber of Patent Attorneys, chair of the Patent and Utility Model Law Committee of the German Chamber of Patent Attorneys, and a board member of the German Association for the Protection of Intellectual Property and Copyright (GRUR), District Group West.