Metal Replacement Close to the Engine

New Heat-Resistant Polyamide for Hot Air Applications

Increasing environmental awareness, high oil prices and changing political conditions are more and more focusing attention on the energy efficiency of automobiles. Lightweight construction, and thus the use of plastics as a substitute for metal therefore plays a key role. However, due to the increasingly growing demands, it is becoming more difficult to replace metal with polymeric materials, especially in the hot area near the engine: High-performance plastics are frequently ruled out because of the system costs. On the other hand, the performance capability of the remaining plastics no longer satisfy today's requirements.

With the new polyamide (PA) specialty grade Ultramid Endure, researchers at BASF have now succeeded in finding a way out of a dead end. The material is a glass-fiber-reinforced polyamide that combines outstanding resistance to heat aging with the good processability of PA 66. Compared to the standard PA 66 grade Ultramid A3WG7, the processability has been improved notably as well. Thanks to this combination of characteristics, it is now possible to produce, at justifiable system costs, under-the-hood components that are exposed to very hot air and significantly contribute to further weight reduction.

Long-Term Heat Resistance Through New Stabilization

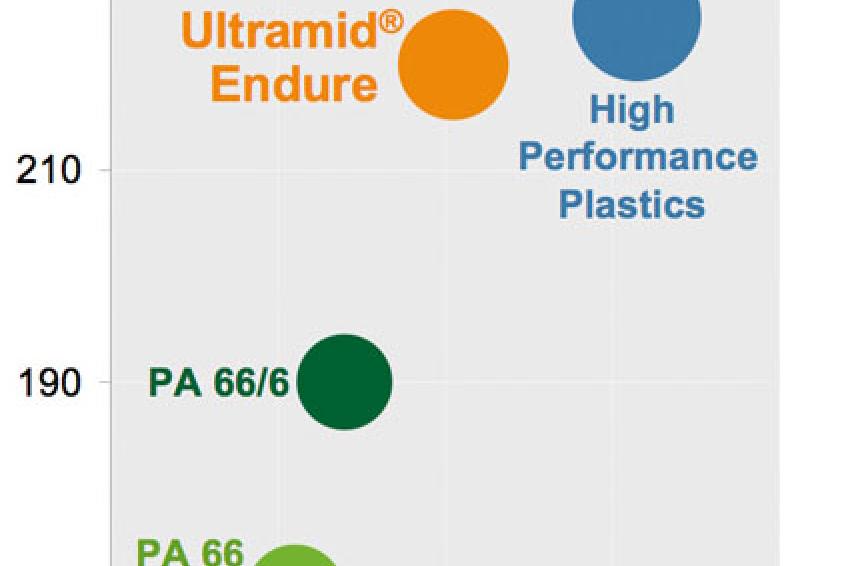

The new Ultramid Endure easily withstands continuous use at temperatures up to 220°C as well as spikes up to 240°C. This extends the field of application of polyamides into the high-temperature realm. For comparison, Ultramid A3WG7 with the same glass-fiber content has a long-term service temperature of 170°C, while products in the heat-resistant Ultramid W2 line (PA 66/6) such as Ultramid A3W2G6 can withstand 190°C in continuous use (Fig. 1).

This enormous improvement in resistance to heat aging is achieved through innovative stabilization technology. Formation of a protective surface layer even at temperatures up to 220°C provides continuous protection against oxygen.

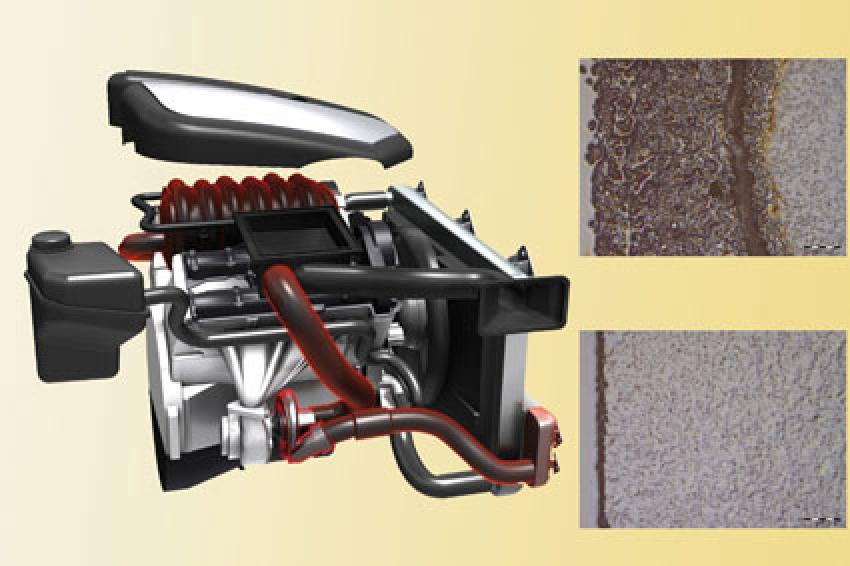

The effect of this technology can be seen especially well on aged surfaces. In conventional PA 66, oxygen has eroded channels in the surface after 1,000 h at 220°C, allowing ever more oxygen to reach even deeper layers. In Ultramid Endure, the surface is sealed off very quickly by the new stabilization and sealing process, so that the material remains protected - except for a thin layer of carbon black on the surface - even after four months at 220°C.

Under-the-hood components are frequently bonded together by means of welding. As a result of the lower glass-fiber content, the weld line can create a weak spot, especially after aging. The new stabilization mechanism not only protects the polymer itself, but also strengthens this potentially weak spot. Weld lines also withstand continuous use at elevated temperatures very well. No cracking at the joint is evident even after 1,000 h at 220°C. Weld line strength remains high as well.

Benchmarking Passed with "Very Good"

Thanks to this stabilization, the Ultramid Endure retains its high strength in fatigue tests at 220°C even after 3000 h, while considerable declines appear after a relatively short period of time in PA 66/6 and in even stronger thermoplastics such as PPA.

In addition to the effect of aging, material properties at the continuous operating temperature play a decisive role when designing a part. The toughness and strength values are especially important. If they are high enough, wall thickness can be reduced without endangering part integrity. The Ultramid Endure also performs exceptionally well in this regard. Its break stress at 200°C lies considerably above that of comparable products (Fig. 2 and Fig. 3).

In addition to the performance of a part, system costs are an important criterion for developers. They are determined to a large extent by the processability of the material used. The new plastic offers problem-free processing with a noticeably wider processing window than other high-performance plastics.

A Material for Modern Engine Concepts

As a result of the trend towards higher energy efficiency in automobiles, engine compartment temperatures continue to rise. For instance, automakers today are attempting to improve energy efficiency through turbocharging, among other approaches.

Turbocharging, i.e. increasing air intake, allows the performance of the engine to be shifted to an operating point characterized by better fuel consumption. This requires use of turbochargers, which generate higher pressures and temperatures in the engine compartment, especially in the charge-air duct. In turbocharged diesel engines, for instance, operating temperatures up to 200°C are common in the region between the turbocharger and intercooler and can spike to 230°C.

At the same time, automakers would like to replace metal with plastic for weight reasons, and at the lowest possible cost. Until now, there were no acceptable alternatives (from the standpoint of costs) to the considerably more expensive high-performance resins in this temperature range. Ultramid Endure, with its exceptionally good heat aging behavior and good processability, now fills this gap and will raise the amount of plastic used in the charge-air duct of diesel engines significantly. Possible applications include all components of the charge-air duct such as intercooler end caps, resonators, charge-air lines and throttle valves as well as components on the somewhat cooler side of the turbocharger. Intake manifolds with integrated water-cooled intercoolers could be an additional future application for the new material. The high temperatures associated with these special intake manifolds push classical intake manifold materials (PA 6) to their limits.

This new specialty polyamide from BASF will be introduced at the K show 2010. Sample quantities will be available in Europe as of October.