Reinventing Sustainable Value Creation

Why the Chemical Industry Must Decouple Economic Growth from Ecological Footprint

In the last several years, we have witnessed global trends that are changing the way global chemical companies operate. These trends include a consolidation of suppliers, manufacturers and buyers; the shift of growth to emerging markets and higher market volatility with faster transfer of information. But these trends are not the only developments having an impact on our business.

The acceleration in global economic activity and continued population growth are putting immense pressure on our planet's resources. In this context, we, as an industry, must address the relationship between economic growth and resource consumption. Can we grow despite the sustainability challenges that we face? The answer is 'yes' but we need to become more efficient, i.e. create more value with a smaller footprint. We cannot afford to pursue economic growth alone. The chemical industry, in particular, has already done a lot to decouple growth from footprint but there still is some way to go. We can and must do better.

Vision 2050

Creating value in this new reality requires a clear vision and transparent goals. At Henkel, we are working with Vision 2050 developed by the World Business Council for Sustainable Development (WBCSD). The vision states: "In 2050, 9 billion people live well and within the resource limits of the planet."

This vision is the basis for our strategy of "achieving more with less." We need to create more value - for our customers and consumers, for the communities we operate in, and for our company - while reducing our environmental footprint.

By 2030, we want to triple the value we create through our business operations in relation to the environmental footprint of our products and services. We summarize this ambition to become three times more efficient as "Factor 3." Our sustainability strategy summarizes the objective of every business to achieve more value with fewer resources and therefore demonstrates that sustainability is a critical factor to be competitive.

Driving Sustainability along the Value Chain

Creating more value can be achieved through our partners, our products and our people. Only by joining forces can leading chemical companies drive sustainability along the value chain. That's why we have been developing innovative solutions and setting new standards together with our partners to manage complexity and risk in our global value chains.

For example, in 2011, we and five other companies in the chemical industry established the "Together for Sustainability" initiative (TfS) to harmonize the increasingly complex supply chain management processes and to optimize the dialogue among business partners worldwide. At the heart of the initiative is the idea that "an audit for one is an audit for all." With TfS, suppliers only need to pass one assessment or audit performed by independent experts. 1,100 audits and assessments were carried out under the TfS initiative at our suppliers last year and 90% of the suppliers who underwent a repeat audit had improved their sustainability performance. In 2014, the initiative turned its focus toward emerging markets, particularly those in Asia. The intention is to actively involve suppliers in sustainability assessment processes and audits.

Incentivizing Suppliers to Develop Sustainable Solutions

We need to incentivize our suppliers to develop new innovative and sustainable solutions. At Henkel, we work with strategic suppliers on process optimization, resource efficiency, environmental and social standards, as well as innovation. In addition, we have been recognizing strategic supply chain partners that make the biggest contribution to sustainability for each of our three business units since 2011. BASF, Croda, Evonik, Monosol, Novozymes and Solvay are among the strategic partners that have received an award for their outstanding contribution.

Partnership should not be limited to cooperation between a company and its own suppliers. We, as an industry, should make all efforts to safeguard existing, and create new sustainable renewable feedstocks for the value chain. We are committed to zero net deforestation by 2020. Therefore, the palm and palm kernel oil that we use should not contribute to deforestation of primary or secondary forests with significant ecological value. We are working with our partners to establish full traceability of palm and palm kernel oils used in ingredients for our products, such as surfactants, by 2020.

We are providing targeted support to plantations and smallholders in palm-growing countries to promote sustainable farming practices, improve livelihoods and ensure that sufficient volumes of sustainable oil are available on the market. After developing our first smallholder project with NGO partners in Latin America, we have recently signed a second project in South East Asia.

Industry - Academia Collaboration

Creating superior value also means that the businesses and the academic community must come together to work on innovative sustainable solutions. This partnership is extremely important for Henkel and that's why we started a cooperation with the Technical University (RWTH) in Aachen, Germany. There, we are researching and developing the laundry and home-care solutions of the future in the "Henkel Innovation Campus for Advanced Sustainable Technologies" (HICAST).

The cooperation has three objectives: to find new sustainable feedstocks that can be used as raw materials in our products, create high- performing ingredients and exploit unknown synergies between new and existing washing agents. The unique advantage lies in the seamless cross-disciplinary cooperation of four professors and their research teams specialized in process technology, biotechnology, as well as physical and polymer chemistry.

We expect game-changing innovations, which will significantly contribute to better performance, resource use efficiency and preservation of the climate, from the cooperation.

Revolutionizing Product Development

Based on internal innovation and our partners´ support, our products must deliver more value at a reduced ecological footprint. That's why we systematically integrated our sustainability strategy into the innovation process in 2008. Each new product has to demonstrate a specific advantage with regard to the focal areas of our sustainability strategy, i.e. performance, social progress, safety and health, energy and climate, water and wastewater as well as materials and waste.

These focal areas summarize the main challenges of sustainable development as they relate to our operations. The idea is to start with a qualitative assessment of the sustainability contribution at the very beginning of every research project and turn it into a quantitative evaluation, which ends with a life cycle analysis (LCA) for the final product. This year, we reinvented the approach by integrating the planned sustainability contribution into the briefing phase of the new product development.

Henkel Sustainability#Master

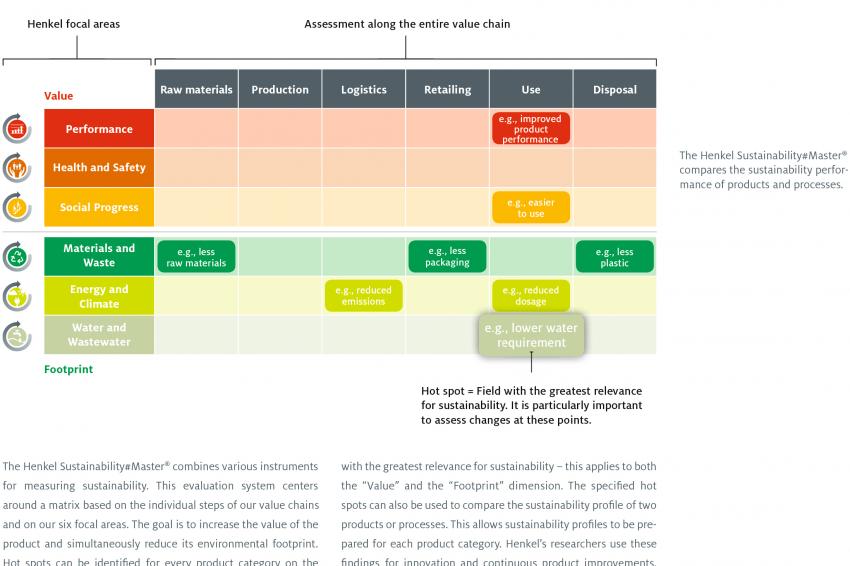

Innovation will reinvent the industry's contribution to a more sustainable world. It starts with the identification of sustainability "hot spots" for each product or category. These are areas where a particular product can have a very significant positive impact - when designed in the right way. Unfortunately, there are not many tools available to monitor a company´s product portfolio, especially for small and medium-sized enterprises.

That's what motivated us to create the "Sustainability#Master" to systematically measure and continuously improve a product's sustainability performance. It consolidates information from life cycle analyses, stakeholder feedback and external product requirements. At the heart of the system is a matrix with 36 fields mapping the entire value chain from raw materials to disposal on the one axis and all six focal areas of sustainability from performance to waste on the other axis. That makes it very convenient to check which field makes the biggest difference when improved.

The Henkel Sustainability#Master serves as a communication tool. The Marketing and Sales teams fill it with specific product information and adapt it to suit each specific regional market. It is also widely used as a presentation tool in dialogue with retail partners, non-governmental organizations, research institutions and other stakeholders.

Engaging Employees

Finally, every company in the industry must engage its employees around the same sustainable goals to create value globally. Our shared vision and our corporate values are what unites us worldwide to create more value and build our success. If we want to achieve our goal for 2030, we need everyone to contribute. That's why we strive to give our employees a clear understanding of sustainability and enable them to convey the importance of sustainability to others. Our Sustainability Ambassador program was launched in 2012 to engage employees more deeply on the topic of sustainability. Since then, Henkel has trained more than 3,800 Sustainability Ambassadors - including all Management Board members - in 70 countries. Since the start of the program, the Sustainability Ambassadors have educated about 36,000 children in 37 countries.

In summary, the industry has a very important role to play in decoupling growth from footprint if we want the world population to live well by 2050. We have to face our responsibilities and reinvent sustainable value creation wherever possible. And for us, sustainability is not only a responsibility but also a great opportunity to continuously improve and to strengthen our competitiveness. Sustainability has already become a key differentiator for business success.

Contact

Henkel AG & Co. KGaA

Henkelstr. 67

40589 Düsseldorf

Germany

+49 211 797 0

+49 211 798 4008