Cellulosic Ethanol: Future’s Fuel

Sustainable Biofuel Production Becomes Reality

Nature's Building Block - It looks like that the time of cheap oil is over. The challenge of this century will be the exploitation of alternative resources to secure growth and quality of life for an ever growing population.

Thus, a small molecule has come into the focus of attention: glucose, nature's chemical building block. The conversion of sugars into chemicals such as ethanol offers new and sustainable alternative routes independent from fossil-based production to chemicals and fuels and with substantial savings in CO2 emissions.

Sustainable Cellulosic Ethanol

One of the biggest consumers of crude oil is the transport sector - it uses up to 70% of global oil production every year, causing about 25% of global CO2 emissions. Thus, biofuels are the primary route to more sustainable mobility and to more independence from fossil resources. Worldwide, bioethanol is the most important biofuel with an annual production of 85.8 billion liters in 2010, and counting.

Recently, the sustainability of biofuels has been discussed intensively. Not only greenhouse gas emission savings vary widely depending on the used feedstock and process, also the competition to food and feed production and land use change issues may have a negative impact on the overall effect.

Cellulosic ethanol is bioethanol made from lignocellulosic feedstock such as agricultural residues or dedicated energy crops. Only non-edible parts of the plant are used for its production. It constitutes a new energy and chemical feedstock source, using an already existing renewable feedstock with no need for further production capacity, giving added value to a byproduct from agricultural food or feed production. High greenhouse gas emission savings of up to 100% can be achieved.

The demand for cellulosic ethanol is predicted to increase over the upcoming years in all industrialized countries and emerging markets. Legislative measures such as blending quotas or taxation and a growing demand for biobased ethanol from the chemical industry will support the market growth for cellulosic ethanol. In addition, agricultural byproducts underlie less price volatility as the feedstock is not transportable over large distances and such is only locally marketable.

Huge Potential

The worldwide potential of biomass is huge. In the U.S., the annual production of agricultural residues (cereal straw and corn stover) reached almost 384 million tons in 2009 and Brazil alone produced more than 670 million tons of sugar cane in 2009 yielding more than 100 million tons of bagasse (dry basis).

Alone in the European Union, almost 300 million tons of crop straw are produced annually. At least 60% of the straw can be taken from the field without endangering soil quality and humus balance. Just the amount of cellulosic ethanol produced from this feedstock would be sufficient to substitute more than 20% of EU gasoline demand by locally produced biofuel.

And these are rather conservative figures: a recent study by Bloomberg New Energy Finance estimates that until 2020 between 52% and 62% of the European predicted gasoline consumption could be substituted by cellulosic ethanol. This would result in potential greenhouse gas emission savings of 42% to 50%, according to the report.

Considering the fact that engine and automobile technology will advance continuously underlines the huge potential of this new technology. And this can be achieved just by the utilization of an already existing renewable feedstock, without needing any additional land or production capacity.

In the EU about 1,000 cellulosic ethanol plants would be needed only to exhaust the existing straw potential. This would result in additional income for the agricultural sector, the creation of several 100,000 new "green" jobs and would significantly reduce EU's oil dependency.

Straw for the Tank: More than a Vision

The technology for the production of cellulosic ethanol has matured a lot over recent years. Large scale production is more than a vision nowadays. First demonstration and pilot projects are up and running or soon to come. One of these projects is the sunliquid demonstration plant of Munich-based Süd-Chemie, a member of the Clariant group, is a leading specialist in catalysis and adsorbents technologies as well as biocatalysis. The sunliquid technology sets a good example for how to overcome the most important challenge in cellulosic ethanol production: the costs.

The main technological challenge in the production of cellulosic ethanol is the breakdown of the stable lignocellulosic structure into sugar monomers. To achieve this, an enzyme mixture is added to the pretreated feedstock. These enzymes used to be one of the major cost drivers.

Through intense optimization, Süd-Chemie developed highly feedstock and process specific enzymes that convert the plant material into the corresponding sugars with high efficiency, hence, resulting in high yields at short reaction times. The enzymes are produced process integrated on a small portion of the feedstock, keeping costs to a minimum and avoiding short passes in supply or price volatility.

Another way to reduced production costs is optimization of ethanol yield. Süd-Chemie's sunliquid uses a fermentation organism that can simultaneously convert C5 and C6 sugars into ethanol in a one-pot reaction, thus increasing ethanol yield by about 50% compared to other processes that use only C6 sugars. A new separation technology and the holistic process design optimized energy demand so the process is energy self-sufficient by only using the residual lignin further contributing to its overall economic viability.

All-Rounder Glucose

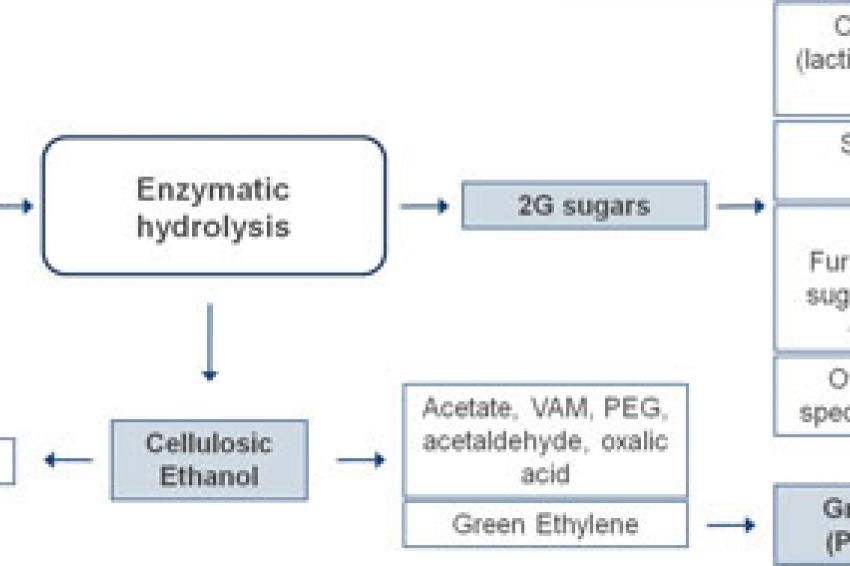

But cellulosic ethanol is not just valuable as a biofuel. It is the fundamental building block for green chemicals. Through further conversion it can be transformed into bulk chemicals like acetate or acetaldehyde or to ethylene, the monomer of polyethylene production, the most important plastic worldwide.

Furthermore, the sugars obtained after the first hydrolysation step of lignocellulosic feedstock open up a variety of different product routes. Via fermentation these second generation sugars can be converted into further specialty and bulk chemicals. Big companies like Coca-Cola or Procter & Gamble have set themselves targets to increase the biobased content of their products. Thus, the demand for green chemicals has increased over the last years and will further grow. A second generation sugar platform is essential to fulfill this need in a sustainable and efficient way by avoiding a food competition.

Summary

Biomass will play an important role in our way to a more sustainable society. In transport as well as in the chemical industry, cellulosic ethanol and green chemicals from lignocelluloses can make a major contribution. The technology is there and ready for commercialization. What is needed now is a stable environment for investors to unlock its whole potential and to secure Europe's leading position in chemical innovation.

Support measures are needed to bridge the so-called "Valley of Death" from research to innovation. Only with these measures in place, cellulosic ethanol and green chemicals from lignocellulose can make a difference in the short to medium term.

Contact

Süd- Chemie AG

Staffelseestr. 6

81477 München

Germany

+49 89 710661 0