SQAS Helps Access Safety, Quality in Logistics

Chemical companies need assurance that logistics and distribution operations are carried out in a safe and high-quality manner.

Streamlined System - The chemical industry in Europe utilizes to a large extent the logistics services offered by third parties to store, handle and transport raw materials, intermediates and finished chemical products. The chemical industry also partners with chemical distributors as an essential route to certain customers.

Chemical companies need assurance that these operations are carried out in a safe and high-quality manner with due regard for the protection of employees, the public and the environment. In the past, this assurance has often been obtained by individual chemical companies undertaking periodic audits of their logistics service providers and distributors, leading to a fragmented approach and a multiplicity of auditing programs, which was costly and inefficient for the chemical, transport and distributor industries.

SQAS Basics

In 1992, the first trials of a pioneer system to assess haulers were carried out. Twenty-one years later, the Safety and Quality Assessment System (SQAS) has obtained wide acceptance in standardizing assessment procedures for logistics service providers and distributors of the chemical industry in Europe.

SQAS provides a tool to assess the quality, safety, security and environmental management systems of logistics service providers and distributors in a uniform manner by independent assessors, using a standardized questionnaire. SQAS helps chemical companies in the process of selecting logistics service providers or distributors and in defining improvement actions with each of them.

An SQAS assessment by an independent assessor does not lead to a certificate but results in a detailed factual report, which each individual chemical company needs to evaluate according to its own requirements.

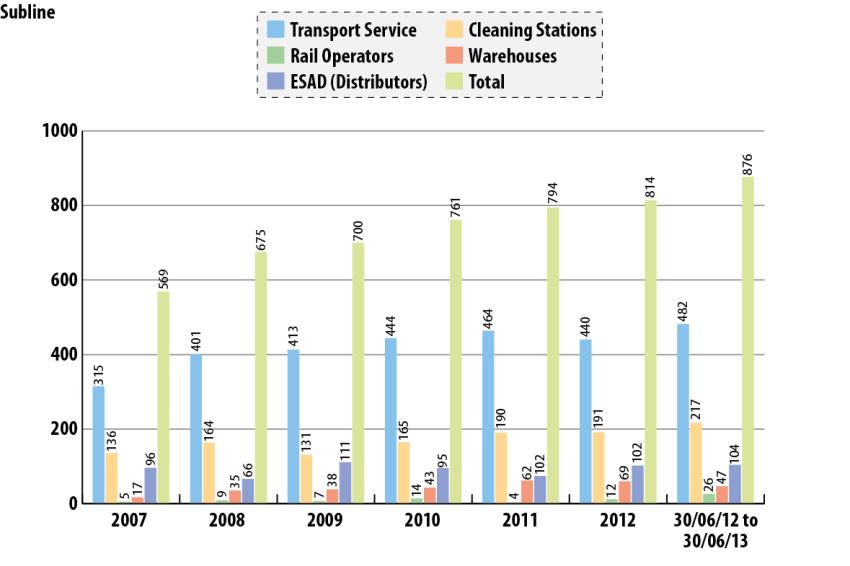

SQAS includes five modules that can be combined to cover the different activities of the company to be assessed: transport service, tank cleaning stations, warehouses, rail operators and distributors (called ESAD).

Growing Population

A total of 814 assessments were made under SQAS and ESAD in 2012, a record number with increases seen in Spain, the Netherlands and the UK. By the end of 2012 there were 2,308 active reports in the SQAS database, of which 1,319 came from transport companies and more than half the remainder from cleaning stations. There has been a sharp increase in the number of warehouses being assessed under SQAS in recent years, with 170 such facilities active in the database at the end of 2012. There is still a growing trend, and another record in the number of SQAS assessments is expected by the end of this year.

Support from the Chemical Industry

There are now 44 chemical companies supporting and using SQAS, as well as 18 chemical companies using ESAD. Ninety-five logistics companies and chemical distributors are part of the Logistics & Distributors (L&D) User Group, which all have access to reports of other logistics companies when those reports are authorized for release. Participation in the L&D User Group is open to any transport company or chemical distributor that has been assessed under SQAS or ESAD.

And it is not only logistics service providers who are being assessed. In March of this year the European Chemical Industry Council (Cefic) undertook a survey about the quality of its assessors. A questionnaire was sent to 93 assessed companies, randomly selected, of which 36 responded. All of them rated the assessors as good or excellent. The survey will be repeated again before the end of this year.

New versions of two relevant documents related to the SQAS system were issued this year: The SQAS/ESAD 2012 Guidelines and the SQAS Accreditation Manual. The first document explains the main features of the SQAS system and the second the rules for candidates to become SQAS assessors and to maintain their accreditation. The documents can be downloaded from the SQAS website here.[BS1]

Checking L&D Performance

Cefic has calculated the average "yes" score for each subsection of the different SQAS modules (transport service, tank cleaning, warehouses, rail operators and distributors) and there is some consistency in those that have the lowest scores. In broad terms, they deal with service partners and contractors, security, and the use of behavior-based safety programs. Risk assessments and management review are important areas for improvement in tank cleaning stations. For chemical distributors under the ESAD assessment, issues such as community interaction, product stewardship of food products and the transport of unpacked food products are aspects to improve. It is notable that Cefic itself is addressing some of these issues by issuing guidelines jointly with the European Chemical Transport Association (ECTA) on, for instance, behavior-based safety and loading/unloading procedures.

The SQAS website allows the user to carry out statistical analysis and generate meaningful data to find out areas of improvement. The most significant value in such analysis is that it allows all assessed companies to benchmark themselves against industry at large. Each company can see exactly where they lag behind the industry average and, where there is not a good reason for such divergence, can target its resources toward improving its performance. Each SQAS user can simultaneously compare up to 15 assessment reports, whether they refer to subsidiaries of the same company or different companies.

SQAS in the World

SQAS is also breaking out of its European bounds and being taken up by chemical trade organizations in other parts of the world. Local versions of SQAS have been introduced in Brazil, South Africa and China. Cefic manages SQAS in Europe and it is supporting the development of similar systems in other parts of the world.

Cefic is currently helping Gulf Petrochemical and Chemical Association (GPCA) to develop a SQAS system in the Gulf Area.

An important part of SQAS, as with all initiatives deriving from the Responsible Care program, is that it should drive continuous improvement in safety and quality standards. As such, it is inevitable that SQAS will develop over time. As long as chemical companies continue to use it as a source of information to improve their knowledge of their logistics service partners, it will continue to be a major element in the ongoing process of improving safety standards in the transport of chemicals, on a global basis.