Supply chain management organisations developing towards a coordinated network model

The Best of Both Worlds

The rise of new markets throughout the world means that all globally active companies must continuously adapt to the developing changes. Ultimately, change never comes to an end. This especially applies to the organisation of supply chain management.

A study which Camelot Management Consultants carried out together with a team from the University of Warwick, UK of the chemical, pharmaceutical and consumer goods industries, shows where SCM organisations in these industries stand at present. CHEManager Europe spoke to Michael Jarosch, Partner and Head of Pharmaceuticals & Life Sciences Practice at Camelot Management Consultants and Julian Amey, Principal Fellow, Warwick Manufacturing Group about the main findings of the study.

The interviewer was Dr. Sonja Andres.

CHEManager Europe: Mr Jarosch, in the future, optimal organisation of the supply chain will play an even more important role in the success of a company on the global market. What are the trends in the organisation and management of the supply chain and which general external factors need to be taken into account?

Michael Jarosch: Globalisation and growth strategies of companies in emerging markets, increasingly volatile global demand as well as the trend to a virtualisation of the supply chain and a geographical shift in sourcing are significantly changing the global footprint of companies and are having a dramatic effect on supply chain management (SCM). In addition there are increasing requirements with regard to compliance and supply chain security as well as the development towards a more sustainable "Green Supply Chain". These have all become a permanent challenge for the core activities of SCM: the reliable, agile and efficient supply of markets and customers with products. The organisation and its necessary development and adaptation to these trends form the basis of successful SCM.

Together with the University of Warwick, GB, Camelot has carried out a study on the subject of "Supply Chain Management Organisation" (SCMO). What was this study intended to discover or clarify and why were the chemical, pharmaceutical and consumer goods sectors singled out for investigation?

Michael Jarosch: On the one hand, the chemical, pharmaceutical and consumer goods industries are primarily process industries with similar strategic and operative challenges and on the other hand they have the full spectrum of SC structures from local to globally integrated supply chains. We have seen that with regard to their general improvement initiatives there are differences between the sectors, for example with regard to their degree of maturity and their efforts concerning the standardisation and harmonisation of business processes. This is therefore a wide field in order to learn from each other, certainly taking into account the basic differences.

However, in all of these sectors, SCM is now an important element of company strategy and organisation, which is continually developing. In spite of this, there is comparatively little information about how companies currently set up their SCM and their rationale.

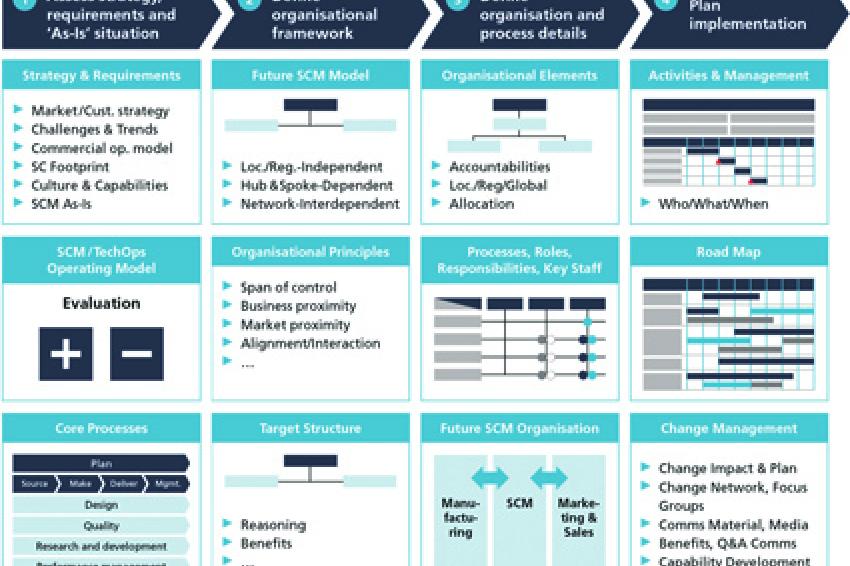

The key question of the study was: Are SCM organisations prepared for and capable of successfully facing up to the apparent trends? In the study we developed a reference framework, which defines various SCM organisation models and explains when these are successful with different strategies. The framework model also helps to examine the consequences of inconsistencies as well as the influencing and success factors for the structure and further development of the organisation.

Mr Amey, what are the basic models for the organisation of SCM in the three sectors which were investigated?

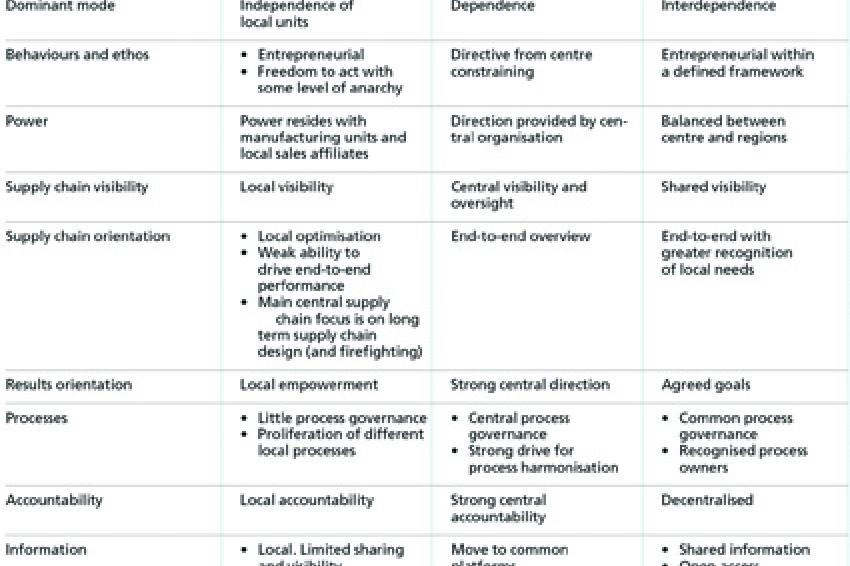

Julian C. Amey: We were able to assign all the participating companies in all three sectors to three basic models: the local/regional decentralised, the centralised "Hub & Spoke" and the coordinated network SCM organisation model.

Characteristic for the local/regional decentralised SCM organisation model is the independence of the local units, i.e. their commercial freedom and authorisation to make decisions in the local production and distribution units. Here, SCM is focused on local optimisation. There is hardly any global standardisation. The SC performance is not visible over the entire chain.

With the centralised "Hub & Spoke" SCM organisation model we find a dependence of the local/regional units on the directives of a head office, with greater global end-to-end transparency of the SC, a high degree of standardisation of processes, central control and a uniform SCM culture with aligned behaviours.

Finally, the coordinated network SCM organisation model has strong interlinking, interdependence and collaboration between the local and central SCM units. It is based on jointly agreed objectives and commercial freedom of the local units within a defined framework. Special local circumstances are taken into account. (See Fig. 1).

What advantages and disadvantages are there for chemical and pharmaceutical companies resulting from the different SCM structures?

Julian C. Amey: The three basic organisation models have very specific advantages and disadvantages. For the local/regional decentralised SCM model, the advantages lie in the entrepreneurial spirit, local SCM performance and consideration of the needs of local markets, e.g. on entry into emerging markets. The disadvantages are the poor end-to-end transparency of the SC, high stock levels and a less competitive cost structure. The central "Hub & Spoke" SCM has advantages with regard to costs, and efficient, harmonised SC and standardisation. The disadvantages lie in the remoteness from customers, the weak "entrepreneurial spirit" and inflexibility. With the coordinated network SCM organisation model, the advantages clearly lie in the balance between costs and service as well as between coordination and local agility. However, the prerequisite for this is an effective governance model.

The study revealed that some companies are converting their central, globally-oriented supply chain management into a local/regional organisation. When does that make sense?

Michael Jarosch: Many of the companies in all of the three sectors which we examined have developed towards a central SCM organisation over the past years. This is due to the need for improved global transparency and control of the SC, together with a harmonization of SCM processes, especially planning. The fundamental prerequisite for this was that SCM IT systems continued to develop and could provide this global transparency.

Nevertheless, companies still face problems regarding the reliability of the supply chain. In particular, the agility of the SC tends to be restricted by excessively rigid central control. This often contradicts the requirement for speed and flexibility which is necessary for growth in emerging markets.

However, the companies are not "going back" to local independence. We are now seeing the first companies which are combining and develop the "best of both worlds" in the form of a coordinated network, with a high level of collaboration to achieve common objectives, agreed responsibilities and joint transparency. This is not a return to local independence but rather a further development towards a coordinated network.

What about the SCM basics such as simplification of processes, data management, IT structures, etc. in the industries?

Michael Jarosch: Our view is very simple: "Fix the Basics!" The companies questioned did not consider themselves to be very good with regard to their degree of maturity in process standardisation/harmonization, master data management and IT support. However these are essential prerequisites for both a centralised Hub & Spoke SCM organisation model as well as for a coordinated SCM network.

There are very different successful models for the management and organisation of the supply chain. How can a company find the optimum SCMO for its business concept?

Julian C. Amey: There is no such thing as a "one size fits all" solution for SCM organisation - even within a particular industry. Each of the organisation models supports specific performance objectives.

Michael Jarosch: For each company, with its specific, strategic and operational objectives, it is therefore necessary to individually examine how the market and competitive strategy, SC configuration and company culture and behaviours can be consistently coordinated, aligned and developed with the SCM organisation. On the journey to this target organisation, factors such as the history of the company (e.g. growth due to M&A), the degree of development of business processes, IT support of the SCM or the critical mass and skills of the SCM staff, both globally and locally must be taken into account.

Can the involvement of 3-PL (Third Party Logistics) providers be an option for the renewal, adaptation of change of the supply chain for the purpose of optimisation?

Michael Jarosch: The use of 3-PL service providers is common practice in all of the three sectors which were examined. Fundamental decisions, which have a considerable influence on SCM organisation relate to the degree of outsourcing of the SC. This concerns both the contract manufacturing as well as logistics and distribution. For a seamless flow in the SC, the company must integrate the external service provider as if it was one of its own units. Interfaces must be jointly standardised. Coordination of the SC does not end at the factory gate. The general objective for the sectors which were examined is to reduce complexity and remain agile. This is something which service providers must come to terms with.

What should e.g. a pharmaceutical company fundamentally take into account in the structural optimisation of its SCMO?

Michael Jarosch: Especially in the pharmaceutical industry, local optimisation of the supply chain is now no longer sufficient, as a global "lean end-to-end SCM" goes far beyond the concept of "lean manufacturing". The need for improvement with regard to virtualisation of the SC is especially pronounced in the pharmaceutical industry. On the other hand, a large proportion of growth is generated in emerging markets with special requirements. In future, a rigid centralism will prove to be too inflexible. In the pharmaceutical industry, the SCM must create a clear view of these developments and the resulting requirements, because only then a development path for the SCM organisation can be defined on the basis of the current capabilities. We regard the skills of supply chain management staff to be a critical bottleneck in supply chain management, which in future will need to go far beyond analytical skills - both globally and locally. Here, the orchestration and decision-making process in SCM in optimisation situations e.g. regarding inventories, production costs and customer service, will be exceedingly important in the future

__________________________________________________________________________

The study can be ordered free of charge at:

http://www.camelot-mc.com/en/about-us/insights/surveys/

Contact

Camelot Management Consultants AG

Theodor-Heuss-Anlage 12

68165 Mannheim

+49 621 86298 0

+49 621 86298 250