Stick to Your Strengths with Biosimilars

25.09.2012 -

Pharmaceuticals - Of the many challenges inherent with biosimilar development, the inability to predict market expectations may top the list for decision makers. While uncertainty is a function of all nascent markets, in the biosimilars world, it has almost seemed to become the norm. In the US, although biosimilar legislation was approved as part of the Patient Protection and Affordable Care Act in March of 2010, it wasn't until the Supreme Court of the United States upheld the law this past June that biosimilar developers knew for certain the abbreviated pathway would remain.

Setting aside uncertainty, many other challenges exist for potential competitors looking to enter the biosimilar market. Regulated markets require expensive, complex regulatory dossiers to gain approval, and in markets void of automatic substitution, additional costs for marketing and sales may be necessary to drive uptake. Provided companies have in-house capabilities to develop and commercialize biosimilars, prior experience working with large molecules may be lacking.

But despite these challenges, over the past few years opportunity within the attractive biosimilars market has continued to grow, giving way to over 200 companies investing in development activities. Regulatory bodies across the globe have established abbreviated approval pathways for biologic products providing both increased competition and cost containment for health systems. Additionally, steps towards regulatory harmonization through the use of a global reference product could reduce the high costs of major clinical programs. Cost-effective manufacturing opportunities such as single-use technologies may provide further relief from cost barriers associated with entering the market.

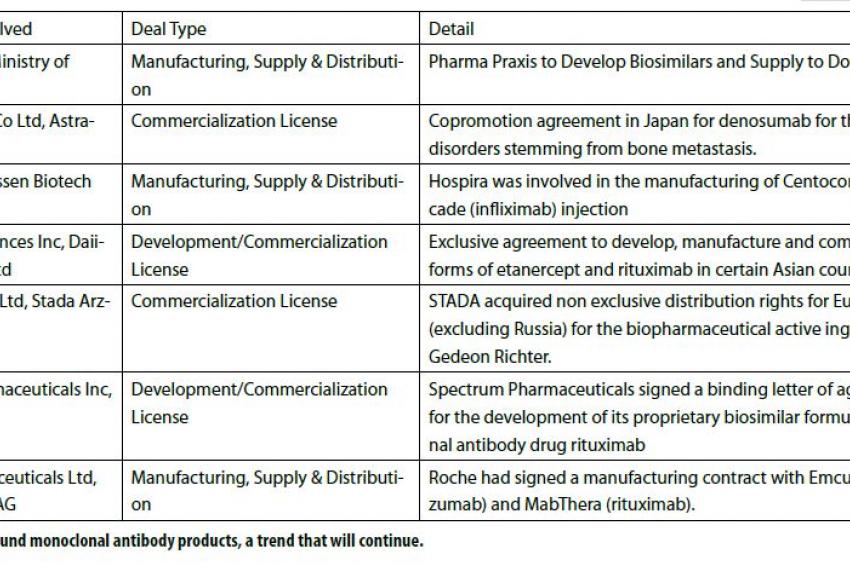

Thus far, the term "buy or build" has aptly characterized the decision companies looking to invest in the biologics market must make. Very few companies are without gaps in one of many important aspects of biologic development including experience, capacity and commercialization know-how resulting in having to either "buy" into partnerships to help fit needs, or "build" in-house capability. Looking at the deal activity from over the past ten years, manufacturing, supply and distribution deals since 2008 have seen significant growth (see figure 1). Also, many companies are focusing deals on complex monoclonal antibody products (see figure 2).

Although many partnerships have focused on providing experience, technology or capacity, a few recent deals have focused specifically on a specific biosimilar candidate. In June of 2011, Merck paid $720 million to license HD203, a biosimilar etanercept developed by the South Korean company Hanwha. In a similar deal, Watson Pharmaceuticals entered into a licensing agreement with Synthon focusing on the Dutch company's biosimilar trastuzumab. Watson will work in collaboration with Amgen on future development of the product from phase III studies through commercialization.

Investing resources or "building" in-house capabilities has been common among some of the more established companies in the pharmaceutical industry. Dong-A of South Korea and Meiji Seika of Japan are investing in a new facility located in Songdo, South Korea that will focus on the development of biosimilar antibodies. Another South Korean company, Samsung, has also invested in building a plant for biologic manufacturing. Samsung partnered with US based Quintiles and has formed a joint venture with Biogen Idec to enter the biosimilars market with plans to construct a facility in Incheon, South Korea.

Which way to go?

But which strategy will provide the lowest amount of risk? The answer, of course, is uncertain. While both strategies can help companies meet the challenges inherent with biologic development, the path to success will most likely not be the same for each competitor. Indeed, perhaps the most important element of strategy design when investing in the biosimilars market is to not drift from proven in-house success. In other words, stick with what you know best.

Boehringer Ingelheim (BI) is one of the most well known contract manufacturers globally. As early as 1997, BI was contracted to do development on biologic products, when it reached an agreement with MedImmune to manufacture the monoclonal antibody palivizumab (Synagis). Over the next decade BI was contracted to develop and manufacture large-molecule products for Novartis, Amgen, and Genzyme, among others. Over years working on different products at a large scale, the company gained valuable experience few companies can claim to share. In 2009, BI leveraged this experience through a strategic alliance with Indian manufacturer Kemwell. Under the terms of the agreement, Kemwell built a new biologics facility which would include BI's Hex technology platform for cell line development. The agreement provides opportunity for BI to drive business through scaling up potential production from the smaller Kemwell plant.

One of the pioneers in the biosimilars market is Novartis' generic arm, Sandoz. Known for developing and commercializing the first biosimilar in multiple regulated markets (Omnitrope), Sandoz has also been a leader in developing other biosimilars, including versions of filgrastim and epoeitin alpha. But where other major generic companies such as Teva and Hospira have turned to partnering for development opportunity, Sandoz has remained dedicated to in-house talent and capabilities. In 2010, Sandoz subsidiary LEK opened a new protein manufacturing facility to help supply the global market for biosimilar epoetin alpha. Sandoz currently has three biosimilar candidates in late stage trials including a version of the monoclonal antibody rituximab.

Moving forward the trend towards deal making in the global follow-on biologic market is not expected to change. Companies will continue to partner and jockey for position in both regulated and less regulated markets, hoping to see a return on whatever investment was made. At the time when uncertainties are no longer and norms have been established, the competitive landscape may look very different than it does now. But which path will provide enough stability to navigate the immediate challenges? The most effective strategy to ensure a long term stake in the biosimilars market may be the one that has already brought success to your company.

Contact

Thomson Reuters

215 Commercial Str.

Portland, Maine 04101

+1 207 8719700

+1 207 8719800