Port of Antwerp: Europe’s Largest Chemical Cluster

Deep-Sea Traffic in the Heart of the Continent

Gateway For Major Players - With 40 square kilometers of chemical industry housing the world's major players, the port of Antwerp may rightfully call itself the largest European chemical cluster. Its central position with easy access to both German and French industrial hot spots and major local production of chemicals make Antwerp an attractive facilitator for chemical companies worldwide. With continuous investments, the port of Antwerp keeps improving its capacity, with proper respect for safety and the environment.

Leading Chemical Companies

Seven of the world's top 10 chemical companies have their plants here. Significant investments are undertaken by the likes of majors such as BASF, TOTAL, Kuwait Petroleum, Lanxess and Evonik. These companies keep their plants in Antwerp competitive and at world-class efficiency levels.

Deep-Sea Traffic in the Heart of Europe

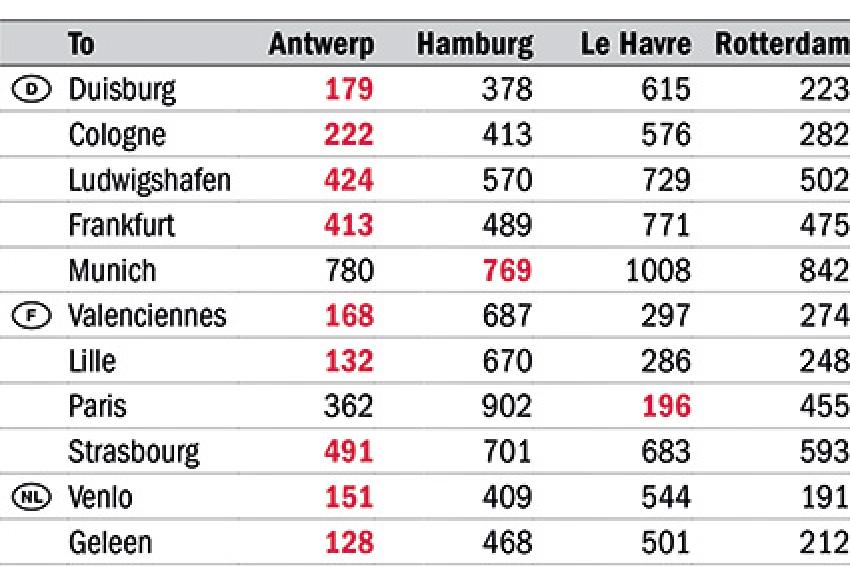

Right in the center of the continent of Europe, the port of Antwerp continues to thrive. Its location is ideal because of the many industrial sites at relatively short distances, which is of course very advantageous for transportation of chemicals. The port also has easy access for deep-sea ships. It can receive Triple E Class container ships and Class LR2 tankers. Its central position and easy access combined with a dense foreland and hinterland network make the port of Antwerp a great partner for the chemical industry.

Largest Chemical Storage Capacity in Europe

The Port Authority and the private sector have invested and continue to invest strongly in expanding the capacity of the oil and chemical sectors. As a result, maritime transport for tank storage companies has grown by 151% in the past 10 years. Over the same period the number of tank storage terminals has risen by 40%, to 15, while the total tank storage capacity has doubled to 6.3 million cubic meters. The port of Antwerp has Europe's largest storage capacity for the petrochemical industry, with nearly 350,000 cubic meters of stainless steel tanks and eight multi-customer plastics terminals with a total storage capacity of more than 430,000 cubic meters. All these terminals operate to the highest standards (Safety, Security, Health, Environmental care and Quality - SSHEQ) for storage and value-added activities.

Important Nodal Point of European Pipeline Network

The port of Antwerp is the most important nodal point for the West European pipeline network. Pipelines offer a safe, reliable and environmentally friendly means of transport for the oil, chemical and energy sectors to supply and distribute their products in Belgium and neighboring countries.

Within the Antwerp chemical and petrochemical cluster, the manufacturing and tank storage companies are connected by more than 100 different product pipelines: Nearly 1,000 kilometers of pipelines transport about 90% of the liquid products within the port.

Antwerp, the largest producer of ethylene in Europe, is connected to the ARG network that supplies all the ethylene to the chemical industry in Belgium, Germany and the Netherlands.

From Antwerp there are numerous pipelines to Terneuzen, Rotterdam, Feluy and the Rhine/Ruhr area.

The relatively short delivery distances within the port of Antwerp, together with the huge pipeline network, ensure fast, safe and environmentally friendly transportation. This correlates very well with the requirements of the chemical companies under their Responsible Care scheme.

Value-Added Logistics

Players in the port of Antwerp offer extensive value-added activities such as breaking bulk and transferring containerized cargo to all possible formats and sizes, blending, tolling, labeling, heating/cooling, grinding, quality and quantity control, temperature-controlled warehouses, vendor-managed inventories, transport and distribution, etc. The port of Antwerp favors an open and competitive offer in logistics for chemicals in all stages of the value chain, tailored to the customer's needs. Goods are handled with efficiency and care, offering a high-quality service.

Combining Speed And Quality

The tailored handling of chemical products doesn't slow down the transit of goods through the port in the least. The high productivity of dock labor, the port's accessibility for the very largest container and bulk carriers and the extensive quadri-mode connections with the hinterland mean that the stay in port is very short.

The logistics service providers active in the chemical sector are world-renowned companies recognized for their high productivity and their innovative, flexible, customer-oriented, no-nonsense approach. The close connections with the largest chemical cluster in Europe ensure that customers in this sector enjoy state-of-the-art facilities and a wide range of value-added activities for packaged chemicals.

Continuous Investments

The port leads not only in size, but also in innovation matched with all necessary investments, both private and public.

The three largest oil refineries in the port of Antwerp - Gunvor, Total and ExxonMobil - together are investing billions of euros in their Antwerp sites. BASF is building a butadiene extraction facility (for more than €100 million), expanding its cyclohexanone capacity (for about €10 million) and investing in additional berthing facilities for unloading seagoing ships and barges (tens of millions of euros). Lanxess is expanding the capacity of its glass fiber plant (€15 million), starting up two pilot plants for developing environmentally friendly chemical bands and investing in a new polyamide plant that is due to become operational in early 2014 (€75 million). FRX Polymers is building a new production unit for a fire-resistant polymer (€20 million). Evonik Degussa is expanding the capacity of its methionine and MTBE production plants and is building additional facilities for producing butadiene. As a consequence of this investment, the neighboring company Oiltanking Stolthaven Antwerp will invest in additional facilities. Ineos Oxide has built a new ethylene terminal. Kuwait Petroleum International is modernizing its lubricating oil plant (€63 million). Sinopec has acquired a 50% stake in Vesta Terminals with the intention of further expanding it. Ferro expands its plasticizer product line by investing in dibenzoates manufacturing capacity. Praxair will build its second air separation plant expanding its production capacity of industrial gases. Praxair also announced its investment in the extension of its pipeline system in the port of Antwerp. Indaver-MediPower is building a facility for environmentally friendly processing of medical and sensitive waste.

The port itself also continues to make significant investments. One of the major ongoing projects is LNG-fueled traffic. Barge LNG bunkering has been available since 2012, and Antwerp plans to have ship-to-ship bunkering ready by the year 2015. The port of Antwerp leads the International Association of Ports and Harbors' (IAPH) workgroup on LNG-fueled traffic.

Expertise Group

To further develop this growth potential, the Antwerp port community has set up an Expertise Group focusing on value-added activities for packaged chemicals. Experts from the Port Authority and specialist private companies examine ways in which the logistics handling of packaged chemicals can be further improved. By bringing the port's strong points further into line with the requirements of the chemical sector, better use can be made of the port's existing advantages. The Expertise Group also acts as a sounding board for the Port Authority for the purpose of developing a proactive strategy aimed at expanding the port's market share in this sector in a sustainable way.

Growing In Difficult Times

Figures show that between 2000 and 2011 the total deep-sea traffic for petroleum derivatives increased by nearly 50%, and maritime flow of liquid bulk for chemicals has more than doubled.

When we look at the evolution of cracking from 1973 until today, volumes have increased from 3 million to 10 million tons. In 1973 there was still no desulfurization. Today the port of Antwerp has 36 million tons of desulfurized product a year.

It's clear that even in today's difficult times the port of Antwerp remains one of the best locations in the world for the chemical industry. It benefits greatly from continuous investments, its strategic location and comprehensive logistical services.

The port has confidence in the future and continues to invest to remain a key partner for the European chemical industry.