Deployable Structures and Self-repairing Materials Inspired by Nature

20.02.2012 -

VIP-Visions In Plastics - Biomimetics is the creative transfer of inspirations from biology into technical applications, a process that typically includes several levels of abstraction and modification.

In biomimetic R&D-projects two main approaches can be discerned: the Bottom-Up-Process and the Top-Down-Process. The Bottom-Up-Process (Biology Push) starts with a finding in biology that is of interest for technical applications, the Top-Down-Process (Technology Pull) with the question from industry for a biomimetic improvement of an already existing technical product. During the last years the fields of light-weight constructions & materials (e.g. self-x-materials), surfaces & interfaces and architecture revealed especially high relevance for application. In addition to an increasing interest in novel and sustainable technological concepts, the development of new methods in analysis, modeling and production have been important factors pushing forward biomimetic R&D-projects.

Bio-inspired Polymer Structures in Elastic Architecture

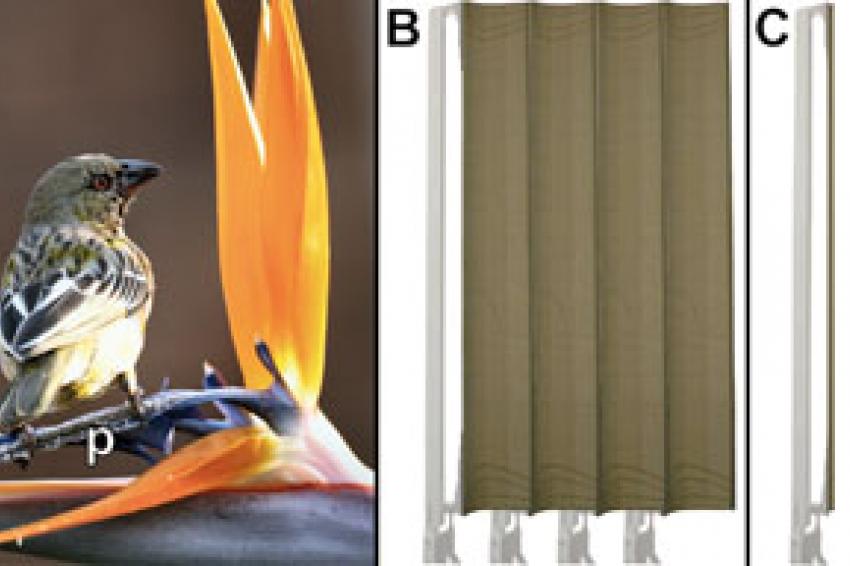

A novel approach was adopted for developing innovative mechanics for biomimetic façade shading systems. To this goal, the kinematics of complex plant movements that are based on reversible elastic deformations were analyzed in an interdisciplinary cooperation between biologists, engineers and architects. This included analyses on autonomous and non-autonomous flower opening and leaf folding processes. An excellent example of this research is the fold-flap pollination system present in the flower of the Bird-of-Paradise (Strelitzia reginae, Fig. 1a). Small birds are pollinating the flower and land on the specially structured perch (p) to feed on nectar. By the bird's weight, the perch is bent down and a thin lamina flaps sideways. Hereby the previously enclosed stamina and style become exposed and pollen can be transferred to the bird's feet and body. This movement is reversible and can be repeated up to 3000 times while retaining almost identical force-displacement curves. The deformation in the flower of the Bird-of-Paradise was abstracted, simulated and transferred to a biomimetic, patent-registered façade-shading system called Flectofin (Fig. 1b-c). Similar to the kinematic in Strelitzia reginae, the sideways bending and flapping of the fin is a movement initiated by torsional buckling when bending the backbone.

In the most-advanced demonstrator of the Flectofin, glass fibers and glass rovings are embedded in a polymer matrix that is composed of an ultra-flexible epoxy resin treated additionally with several dyestuffs to satisfy diverse optical demands. A manufacturing method called vacuum bagging process (VAP-Process) was chosen to guarantee the essential high quality in the Flectofin laminate.

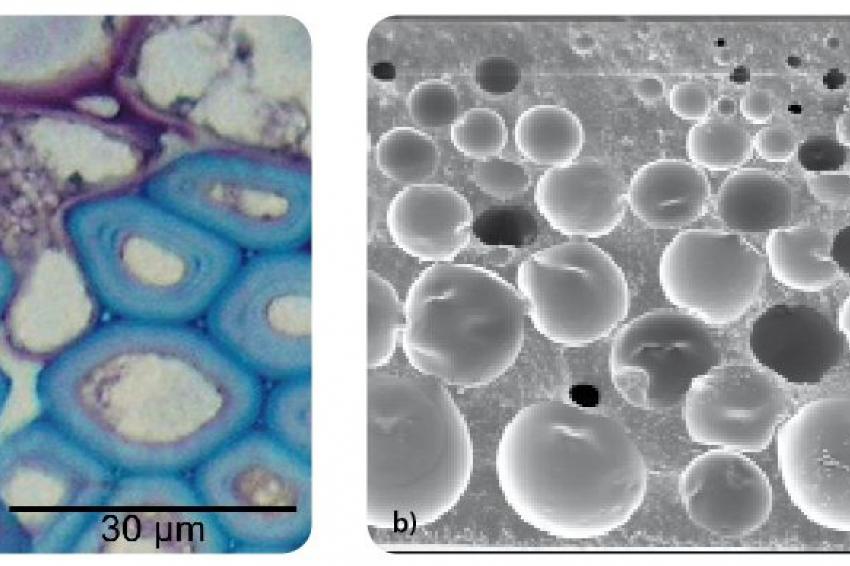

Self-repair is Not a Privilege of Nature

Self-sealing and self-healing are very common in nature. As one can assume a high selective pressure on the evolution of self-repair abilities in nature, independent evolution of these properties including various mechanisms and structures in different plant groups and plant species is probable. Over the last decade plants have proven to be an important source of inspiration for biomimetic self-repairing materials and structures. Studies revealed self-sealing of the sclerenchymatous outer ring in the twining liana Aristolochia macrophylla when fissured by internal growth processes mediated by turgescent parenchymatous cortex cells. Due to their internal pressure these cells expand into the (micro‑)fissures and seal them (Fig. 2a). This functional principle has already been successfully transferred into the development of a biomimetic PU-foam coating polymerized under pressure for self-repairing pneumatic structures (Fig. 2b).

Within another R&D-project Delosperma cooperi, a member of the Aizoaceae family with succulent leaves was selected as a promising role model (Fig. 3a). Growing in arid environments external wounds lead to an exceptional drought stress. Rapid self-repair protects the plant from dehydration and is therefore of eminent selective advantage. After an artificial injury, wound-sealing in leaves of Delosperma cooperi takes place by deformation and movement of the leaf (Fig. 3b). Two principles are involved: (1) rolling in of the fringes of the lesion within a few minutes, and (2) curvature of the entire leaf within 20 to 30 minutes. An analytical model describing the self-sealing process was developed, based on mechanical properties of five hulls, representing the different tissue layers of the leaf.

Impact Energy Dissipation

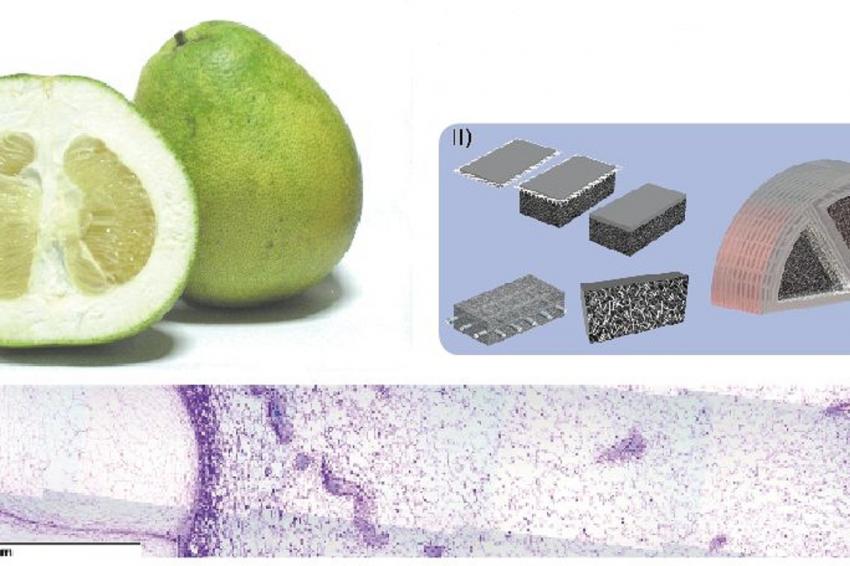

The ability to dissipate large amounts of energy in a fraction of seconds is one major demand on new materials e.g. for protection, packaging, padding and suspension systems. The pomelo (Citrus maxima) is the largest Citrus fruit (Fig. 4a), and provides an excellent biological role model as its thick highly porous peel exactly meets this demand. Under natural conditions the fruits with a weight of about 1 to 2kg drop from trees of up to 15 m height. More than 90% of the initial potential energy of 150J and more is dissipated during ~7ms impact time with negligible damage of the pulp, which from a technical point of view presents the goods to be protected. Rather than having a uniform distribution of pores as found in many standard protection systems based on polymers, the peel proves to be a highly structured composite cellular network based on a sandwich structure consisting of a sequence of closed-open-closed pored layers (Fig.4b). It makes further use of gradual changes in pores size and material distribution between its three different layers to spread the load and to diminish disintegration during loading. Theses structural features have now been transferred in a first approach to a technical system using metal foams to provide enhanced crash absorbers for automotives (Fig.4c). By extending the technical materials to polymers we will be able to cover a much larger range of plateau stresses and thereby vastly increase the area of application. One major advantage of using polymers will be a much simpler transfer of the visco-elastic properties found in the natural role model.

References available from the authors on request.

Contact

Albert-Ludwigs-Universität Freiburg

Fahnenbergplatz

79085 Freiburg

Germany

+49 761 203 98604