Advance with Intelligence

Three Steps to Digitalize Chemical Production

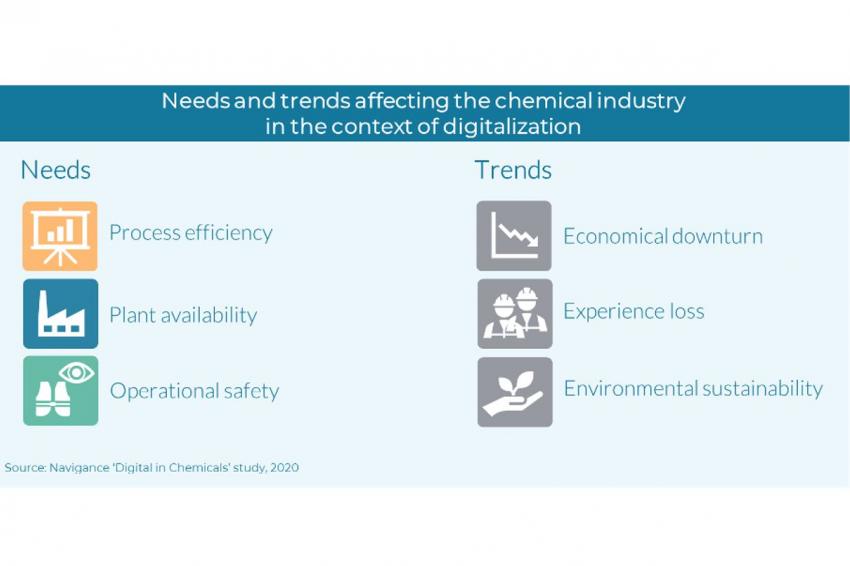

Most chemical manufacturers know they need to digitalize, as industry trends such as economic downturn, lost experience and an increased emphasis on sustainability accelerate and increase the pressure to do more with less.

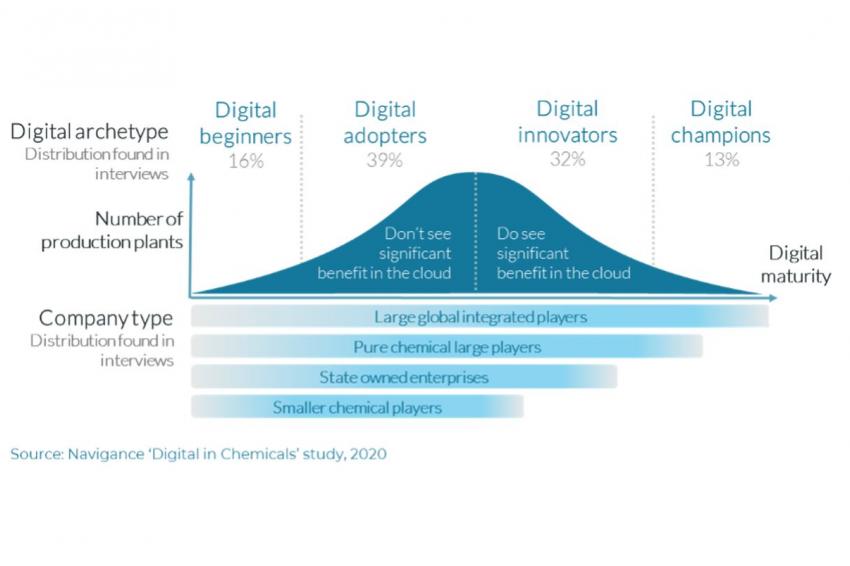

In readiness, producers are already gathering vast quantities of data from sensors across their operations. However, the extent to which they’re putting it to use to inform proactive analysis, targeted action and effective decision-making varies greatly. Some are already reaping the benefits of data-driven analysis with the help of advanced digital technologies like machine learning. Others are much earlier on their digital journey.

If analysis of their data happens at all, it’s usually infrequent, manual and resource-intensive. Its outcomes are often the results of an educated “best guess”, meaning the results vary and opportunities to improve are often missed in a sea of data human eyes can’t hope to interrogate in full. For those plants yet to digitalize or only in the early stages of doing so, knowing where to start and build the business case for technologies to help achieve their critical priorities holds them back from taking these important next steps.

Navigance has produced a whitepaper that explores these challenges and sets out the three steps towards digitalization it believes producers with any continuous chemical process can take, whatever their level of digital maturity. It examines how expert deployment of artificial intelligence and other groundbreaking technologies can help teams increase plant availability and optimize the efficiency of their chemical processes, freeing up rather than increasing the demands on their own time.

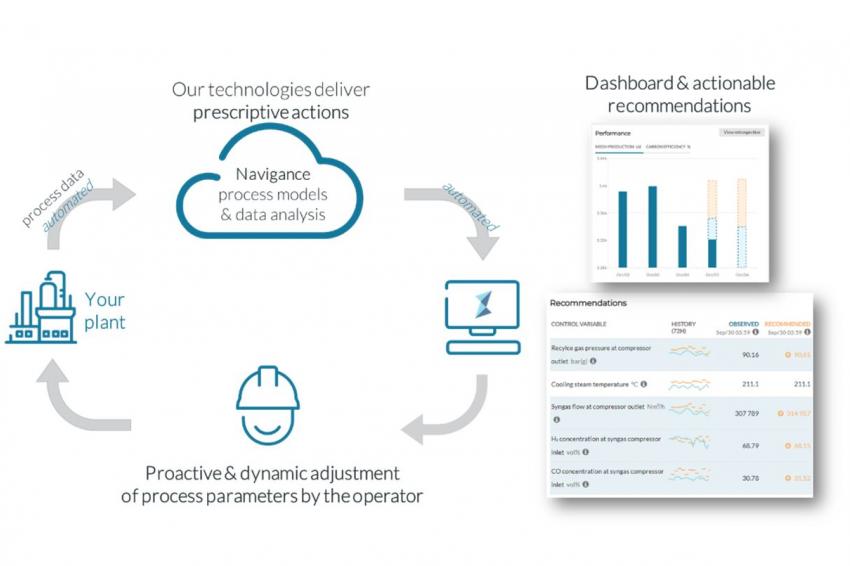

The paper demonstrates how the Navigance Plant Monitor uses machine learning algorithms to scan and interrogate equipment data, spot anomalies and potential issues, and issues proactive alerts plant personnel can act on before plant operations are impacted. The Navigance Optimization Engine, meanwhile, uses cloud-based analytics tools to learn the patterns in process data and identify opportunities to improve, making round-the-clock recommendations plant teams can use to fine tune process control variables and hit their optimization goals.

The paper includes examples of the positive impact these solutions have already had on real plants’ availability and process efficiency.

Crucially, both combine technology and tools with expertise in chemical processes and data science to create tailored deployments that suit the specific needs of each plant that can be deployed quickly. Download the whiter paper from the Navigance website to read more about the digitalization of chemical production and how you can take your next steps on that journey with confidence.