Making Plastics Circular

Take, make, dispose. For decades, this has been the standard approach of production and consumption. Products were used until they were finally disposed of as waste. And this amount of waste grew bigger each year. Only 12% of plastic waste is currently reused or recycled, according to a McKinsey study. The great majority of used plastics end up in incineration, landfills, or dumps, which means losing the material as a resource forever.

As regulators move forward with bans and taxations and consumers shift their buying preferences towards greener products, businesses are under increasing pressure to become more sustainable and adopt a circular economy approach. The global resource demand and its resulting waste have led to a push for action that will profoundly disrupt all industries over the next decade. A report by the Ellen McArthur Foundation shows that by 2040, a circular economy has the potential to reduce the annual volume of plastics entering our oceans by 80%.

From Plastic Waste to Products

Enabling a circular economy of plastic waste into raw materials is top of mind for Mitsubishi Chemical Europe. By using different recycling technologies, resources can be saved, and the environmental footprint reduced. The company offers and sells highly developed chemical-based products, including high-performance engineering plastic, polymer films, and semiconductor solutions, and is the world’s largest producer of methyl methacrylate (MMA).

“Customer demand for sustainable products has been growing in recent years”, says Nicole Kambeck, Circular Economy Director at Mitsubishi Chemical Europe. “In the future, it will no longer be enough to just offer a product that contributes to a circular economy and decarbonization. Additionally, more transparency is needed along the value chain to substantiate environmental, health and safety claims,” she adds. “As a trusted manufacturer, we believe that blockchain technology can address this demand along the lifecycle.”

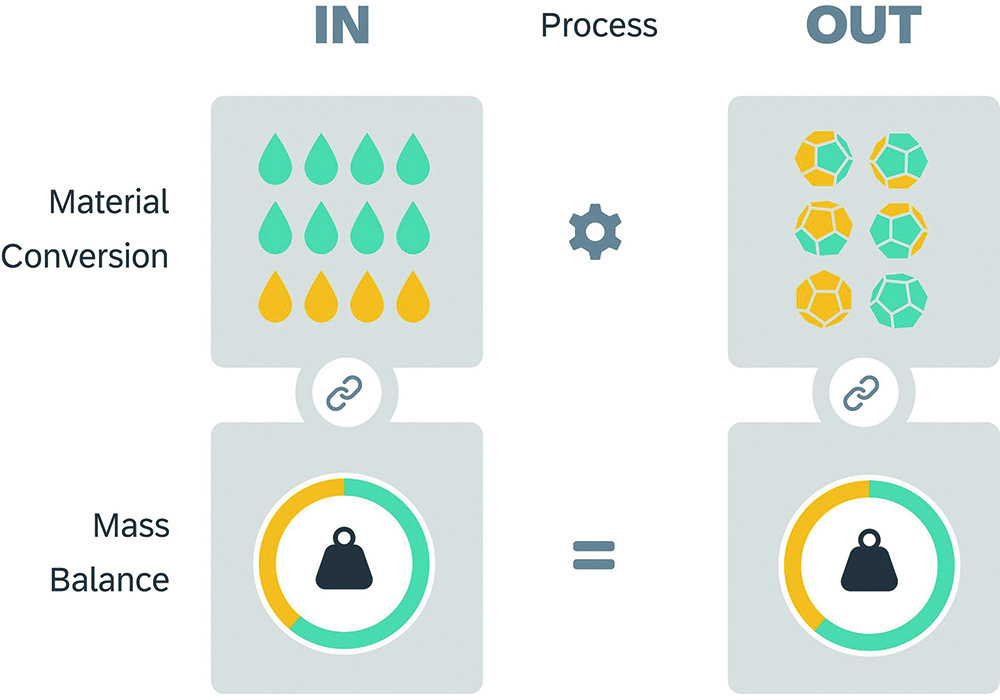

A simplified mass balance overview. (© GreenToken by SAP)

Polymethyl methacrylate (PMMA) is one of the most versatile materials in the world, used in signage, protective Covid-19 screens, lighting, automotive fittings and many more applications. Mitsubishi Chemical aims to build and run a fully operational acrylic recycling plant to break down end-of-life PMMA into its original building block of MMA using a process called molecular recycling. This will then be used to produce 100% circular MMA and circular PMMA.

In today’s global economy, supply chains typically involve multiple parties, and information about the origin of materials is difficult to track — but essential to promote a circular economy along the product lifecycle. To prove to its customers that the plastic they use contains certain amounts of chemical recycled content, Mitsubishi Chemical Europe piloted the GreenToken solution by SAP in their MMA supply chain.

Add Transparency to Opaque Supply Chains

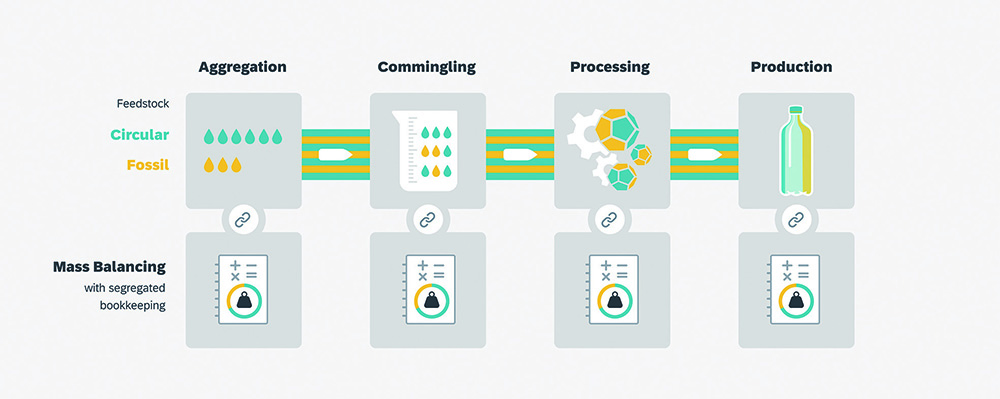

Combining principles of mass balance accounting, tokenization and blockchain, GreenToken enables Mitsubishi Chemical Europe to trace commingled plastic raw material across the global supply chain, from the exact source of origin to the final product. “Usually, the raw material comes from both circular and conventional, non-circular sources. To give transparency to these opaque supply chains, we use tokens that represent the origins of a small, fixed amount of the raw material — 100 kg of raw material could be represented by 100 tokens in our system,” explains James Veale, co-founder of GreenToken by SAP. “We use different colored tokens to represent different raw material attributes, such as green tokens for circular recycled materials and red or no tokens for conventional,” he adds.

Records of these tokens are stored on the underlying blockchain ledger. As the material moves along the supply chain, the GreenToken cloud system passes the equivalent number of tokens that represent the mass of material bought or sold. The tokens are moved from one supply chain actor’s digital wallet to another’s, creating a tracing history — an immutable chain of custody that adds complete auditable supply chain transparency and makes the data trustworthy. Comparing the ratio of green to red tokens instantly gives customers the circular content of their new polymer product.

“Rethinking how we design, make and use resources, requires granular, high-quality data,” says Veale. “Based on the information provided by GreenToken about sustainable attributes of the raw material, such as the percentage of recycled content, Mitsubishi Chemical Europe can make informed decisions on how to meet their circular economy commitments.”

Traceability of commingled materials with mass balance. (© GreenToken by SAP)

Future Circular Business Models

The GreenToken solution serves as a seamless complement and accurate representation of the physical flow of materials through the built-in accounting, allocation, and transfer between various supply chain members. The application of this solution in different value chains can enable new business models in the respective industries, which are required for the transformation towards a circular economy. The abilities offered by tokenization of sustainability attributes will play a key role in the development of future circular business models.

Author: Stefan Gürtzgen, CHEManger