Enjoying Automation

Control For High-Pressure Steam Boiler Systems

Success - At Loos, the acronym SUCcess stands for "Start-Up-Control combined with Shutdown and Standby," a control and equipment variant facilitating automatic steam boiler operation in the operating modes normal operation, heat maintenance, cold standby and hot standby.

At the push of a button or using an external request signal, the steam boiler can be started up fully automatically and gently when cold, shut down and protected against overload during normal operation.

Cold Starts

Cold starts place a considerably higher mechanical load on shell boilers than normal operation. Characterized by the fact that the water in the boiler does not boil, cold starts occur after periods of down time or when multi-boiler systems are used with sequence control without pressure and temperature maintenance (cold standby).

A higher level of mechanical stress is involved because the temperature difference between the flame tube and the boiler shell is greater than in normal operation.

That is why the flame tube expands noticeably more than the boiler shell in normal operation. As a consequence, between the flame and boiler shell or the flame tube and the colder smoke tubes there is considerably more mechanical stress on the respective connecting and stay elements, such as the flame tube floor connection, stay tubes, flame tube reversing chamber connections or gusset stays. This stress is increased even more if there is either no or very limited vapor bubble formation during the start-up procedure, which is the case when the steam shut-off valve is closed, for example.

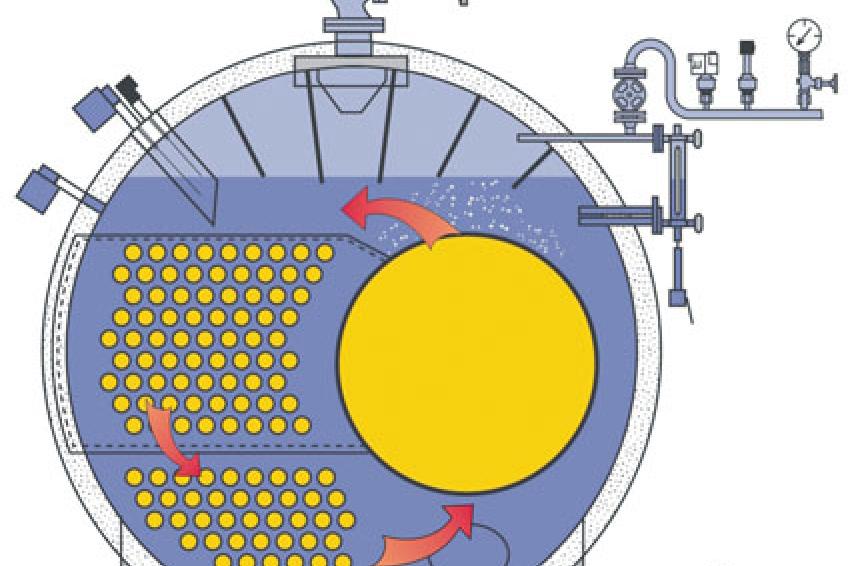

The natural circulation (fig.1) normally found in the steam boiler is not triggered. The result is temperature stratification in the boiler (cold at the bottom, hot at the top) with additional thermal stresses.

Overload and High Load Change Speeds

Every steam boiler is designed to continuously supply a specific nominal output. If the steam extraction quantity rises above this nominal output, the boiler's current working gauge pressure drops even though the burner is operating at maximum capacity.

Depending on the load peak, this more or less rapid decrease in working gauge pressure and the resulting reduction in the boiling point produce re-evaporation effects throughout the boiler's water content. This means that additional vapor bubbles form in the entire water content of the boiler. Since steam has a greater volume than water and the vapor bubbles take a while to rise to the water surface in the steam chamber, the water foams.

On one hand, this can have the negative effect of producing uncontrolled high water or shutdowns due to insufficient water; on the other hand, it can also cause water entrainment in the steam outlet. The negative consequences are wet steam, water impact, corrosion, salt deposits and leaky valves in the steam condensate network.

Great changes in load, i.e. high load change speeds and the associated great fluctuations in pressure, can cause unfavorable flow conditions to develop even if the nominal output has not been exceeded.

The vapor bubble formation required to dissipate heat from the heating surfaces can stagnate, that is, cause many small bubbles to join together to form larger vapor bubbles which do not leave the heating surfaces immediately, thus making conditions favorable for local overheating.

Avoiding Stress And Premature Wear

Due to the reasons stated above, cold starts with steam boilers should be as gentle on the boiler as possible and follow the operating instructions exactly. Until a low working gauge pressure has been reached, the water content should be warmed up with the burner capacity as low as possible. The boiler's water level should be monitored with regard to the water's thermal expansion.

If the water level rises too much, it should be lowered using the blow-down valve. It is important that the boiler water is mixed well during the start-up process. This prevents unnecessary loads in the form of thermal stresses and can be achieved by opening the steam shut-off valve slightly.

A small steam quantity can flow into the connected network. The boiler's natural internal water circulation is triggered. Once the mean work gauge pressure has been reached, the steam extraction quantity should be slowly increased by opening the steam shut-off valve in steps. Water impacts in the lines due to the presence of condensate, steam boiler overload, as well as any unnecessary stress in the pipeline network connected can be avoided by slowly heating up the network.

Overload and High Load Change Speeds

Ideally, these interconnected topics should be taken into account when designing the systems and consumer structure. If great fluctuations in steam reduction and therefore also in the network pressure, e.g. from the steam accumulator, cannot be avoided, automatic units should intervene as needed to limit or prevent steam extraction and thus any resulting negative consequences.

Automatic Start-Up, Standby And Shutdown Control SUC

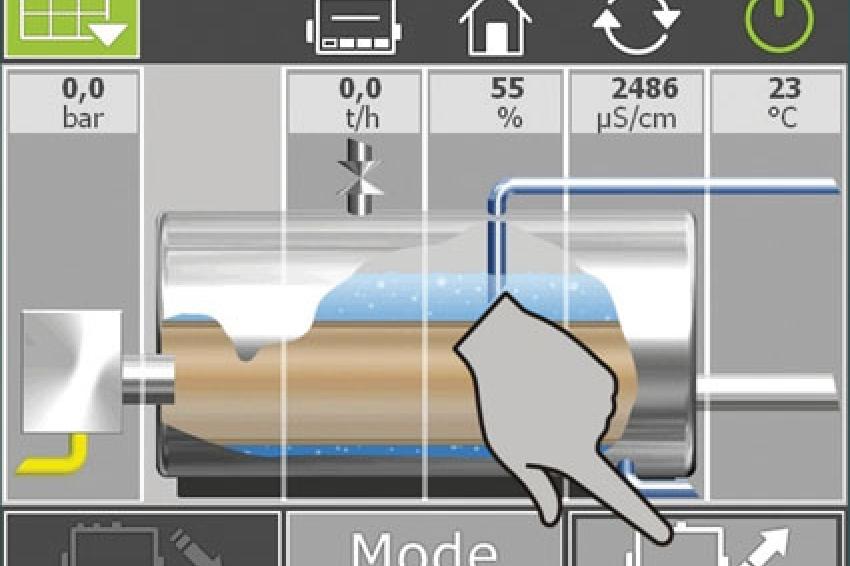

The automatic start-up, standby and shutdown control SUCcess facilitates automatic operation of units that would otherwise have to be operated manually. The steam boilers are equipped with motorised steam shut-off and starting shut-off valves as well as an automatic blow-down valve in addition to the usual boiler equipment.

The control and regulating functions integrated in the LBC boiler management system provide for automatic cold starts that are gentle on the boiler. Overloads and high load change speeds are achieved, and negative after-effects are suppressed using control technology.

Cold Starts Or Cold Standby For Multi-Boiler Systems

The boiler is started up gently at the push of a button or using an external signal. Until an adjustable pressure has been reached, the water content should be warmed up at low burner capacity. The water level is continuously monitored throughout the process and controlled with the aid of the automatic blow-down valve, if necessary. The motorized starting shut-off valve is opened to allow a small quantity of steam to flow off. The boiler's natural internal water circulation is triggered, preventing unnecessary thermal stresses.

Once the pressure has been reached, the steam shut-off valve opens with an adjustable starting cycle to slowly warm up the network downstream. The boiler is now in normal operation.

Shutdown Process

The automatic shutdown process can also be triggered by the push of a button or using an external signal. The steam shut-off and starting shut-off valves (if applicable) close and the burner capacity is slowly reduced until the burner control finally interrupts fuel supply completely. The boiler is now on standby and waits for the next commands.

Reaction to Overload and High Load Change Speeds

The integrated overload protection function ensures that steam quality remains unchanged in the event of sudden jumps in load. If the steam boiler's working gauge pressure is reduced although the burner is operating at the nominal load, this is a sure sign of overload.

The integrated boiler protection control recognizes the problem and reduces steam discharge with the aid of the motorized steam shut-off valve until the boiler pressure is stable again. This prevents water entrainment and its negative consequences, such as brining and corrosion of downstream components.

Heat Maintenance Mode or Hot Standby For Multi-Boiler Systems

During heat maintenance or standby mode (e.g. with multi-boiler operation if the follow-in boiler is not needed), steam discharge is completely suppressed for this boiler.

The burners switch on only sporadically in this operating mode to compensate for losses from thermal conduction and radiation. If this condition is maintained for a longer period of time (> 3 days), temperature stratification begins to develop in the boiler. If boilers kept warm this way are switched to normal operation, the high operating pressure (hot upper range) gives the appearance that the boiler is immediately available. If so required, the boiler control will then charge the boiler within a very short period at high burner load. If there is temperature stratification in the boiler, extreme thermal stresses then occur.

The automatic start-up control intervenes here as well. The starting shut-off valve opens every time the burners are sporadically switched on in heat maintenance mode or hot standby mode. The boiler's natural internal water circulation is stimulated, mixing the boiler water. This prevents temperature stratification and extreme thermal stresses in the boiler.

Customer Benefit

With its automatic protective functions, the start-up control SUCcess ensures that the boiler has a long, trouble-free service life. Operating personnel must no longer carry out a long list of control tasks - one push of a button is now all it takes to cold start the boiler.

During normal operation, the automatic functions intervene in the event of an overload, protecting the system from water entrainment and negative consequences, such as water impact, corrosion and brining of downstream elements. In the heat maintenance phase, steam extraction is facilitated every time the burner is switched on.

This stimulates natural internal water circulation and breaks up temperature stratification. Boiler attendants are relieved of a multitude of tasks, allowing them to focus solely on monitoring and supervisory functions.

Contact

Bosch Industriekessel GmbH

Nürnberger Str. 73

91710 Gunzenhausen

Germany

+49 9831 56 0

+49 9831 56 92253