Broken Supply Chains

Finding the Hidden Costs

In The Red Tape - For decades, governments and companies around the world focused almost exclusively on tariffs as the biggest impediment to global trade. Today, tariffs are at a 30-year low, but trade remains seriously constrained.

The chief culprit? The many inefficiencies, chokepoints and nontariff barriers that hobble global supply chains and increase the costs of trade. Companies ignore these barriers and costs at their peril.

Many corporate leaders know of these obstacles from direct experience. For example, one diversified chemical company exports acetyl and other products to the United States. It needs approvals for every shipment from as many as five U.S. regulatory agencies. The requirement delays 30% of inbound shipments, often causing cancellations from customers who are fed up with waiting.

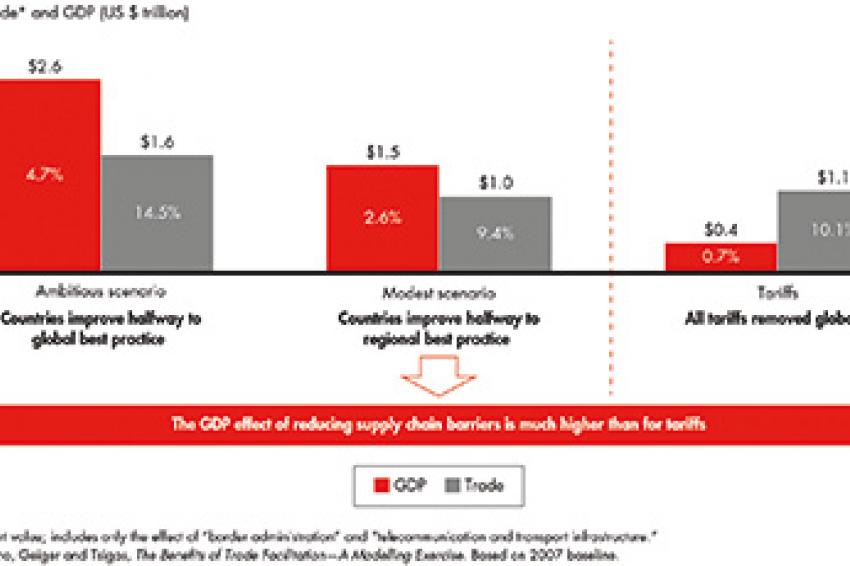

How significant are such barriers overall? Bain & Company, in collaboration with the World Bank, analyzed the business implications of nontariff supply chain barriers - everything from border delays and inconsistent product regulations to poor infrastructure and rampant corruption. The analysis demonstrates that reducing even a subset of these obstructions could bring about an increase in global gross domestic product that is six times greater than the potential increase from removing all tariffs (fig. 1).

These findings have broad, long-term implications for policymakers: They suggest that governments need to refocus efforts on creating supply chain efficiencies if they want to truly unlock the economic potential of global trade. For companies operating in international markets, the message is more immediate. Making the right choices about where and how to deploy assets globally requires full understanding and analysis of how supply chain barriers affect return on investment. Failing to anticipate the costs and risks involved can wipe out the business advantages of sourcing, operating or selling in foreign markets.

Moving Production To Mexico

Over the years, my colleagues and I have worked with many companies weighing the merits of moving production to Mexico, particularly after the North American Free Trade Agreement ended most formal trade barriers on the continent. In doing these analyses, we have been able to quantify supply chain costs and understand how they affect a company's real return on investment.

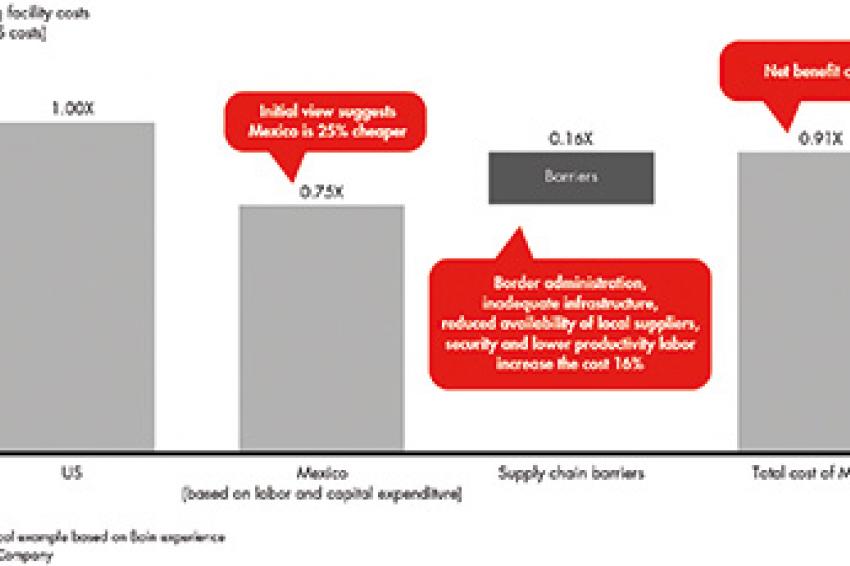

The benefits of investing in Mexico are well-known. Hourly wage rates are about one-fifth of those in the U.S. Capital expenditures related to building facilities are typically 10% less than in the U.S. or Canada. Certain products - nonperishable items with high labor content and high value-to-weight ratio - are particularly well-suited for production in Mexico.

A thorough analysis, however, turns up a number of hidden costs (fig. 2). Mexico's lack of federal and provincial tax breaks can add 1% to investment costs up front. The lower productivity of Mexican hourly workers coupled with a lack of automation means that a company might have to boost staffing levels 25%, erasing some of the labor-cost advantage.

Transporting goods in Mexico is also a problem. Gaps in road and rail connections require shipments to travel extra distances, eating into margins. Safety is a consideration as well. High crime rates in Mexico might require a company to take extraordinary measures to safeguard both its facilities and its goods in transit - putting armed guards on all trucks, for instance. Security measures alone can boost fixed costs by as much as 7% per year.

Many companies have profitable operations in Mexico, and it might make sense for a manufacturer to establish a beachhead there. But the key to all such decisions, regarding Mexico or any other country, is to take a full accounting of all the relevant costs and potential supply chain inefficiencies.

For instance, will delays force a company to stockpile buffer inventories, tying up working capital and adding to direct costs such as warehousing? If so, what risks follow in the form of depreciation, spoilage or production bottlenecks? Companies often fail to take these costs and risks into account, and as a result find themselves locked into uneconomical production and marketing decisions.

Finding Hidden Costs

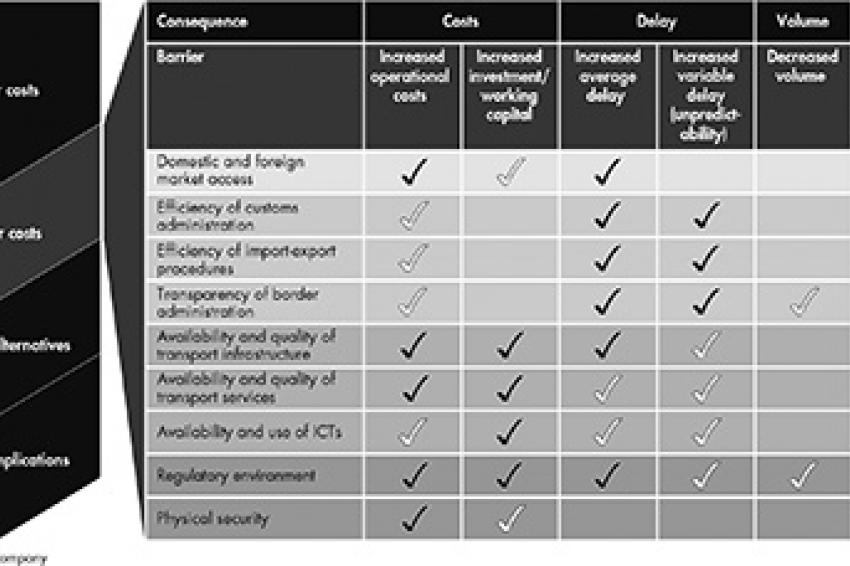

Supply chain barriers to trade are both complex and widespread. A comprehensive approach to foreign investment decisions means recognizing costs in four important categories of the supply chain (fig. 3). Executive teams can begin by asking some key questions relating to each category:

- Market access. How many regulatory agencies will you have to deal with as you move goods into or out of your chosen market? What are the licensing regulations that apply to your product or service? Are there preferential rules or regulations that give local companies an advantage in the market? Will that affect your costs or competitiveness?

- Border administration. What percentage of shipments will be inspected at the border, on average? How does that compare with other markets? What is the typical delay time at a particular border or port, and what will that cost in terms of spoilage, theft or the need to stockpile additional inventories? How often do border officials demand "facilitation payments" to move goods efficiently? Are you prepared for the repercussions of not paying, including potentially severe delays?

- Telecom and transport infrastructure. Does the country have an electronic system at the border allowing shippers to declare goods in advance, speeding up processing? Are those systems reliable and used consistently? How fast on average are trucks or rail shipments able to move to and from key ports? What are the common delays and how costly are they? What special fees, licenses or other regulations do local authorities impose on truckers that add costs or slow the movement of goods?

- Business environment. What are the political and administrative realities in your chosen market, and how will that affect the ease and security of doing business there? Do businesses enjoy the support and encouragement of government officials, or is there a history of random taxation, excessive fees or other attempts to extract value from the private sector? Are the rules and regulations that pertain to your business clear and consistent? Are there established procedures for working through them?

All of these costs can be estimated to gauge the effect on potential investment returns. But if your team can't provide definitive answers to questions like these, moving forward can have real repercussions.

Global trade has increased sharply in the past 30 years, and the opening of markets long considered inaccessible has created rich opportunities for companies of all sizes in every industry. But the companies that get it right are the ones that identify and analyze the real cost of capturing the opportunities - and that avoid the mistake of going in unprepared.

Contact

Bain & Company

Level 22, Phillip Str. 126

Sydney, NSW 2000

Australia

+61/2/90248600

+61/2/90248500