Novel Dynamic Steam Blending System

Avoid Unnecessary Steam and Energy Losses in Modern Industrial Plants

In this novel dynamic steam blending system, steam is fed to the medium to be heated at high relative speed. Due to the dynamic blending, the steam is distributed evenly and finely in the medium to be heated. This enlarges the boundary layers between the gaseous steam and the liquid medium and results in rapid and gentle heat transfer from the steam to the medium because the steam condensates quickly and the formation of steam bubbles is minimized.

The Dynamic Steam Heater consists essentially of the mixer casing and one or two rotating steam manifolds. The steam needed to warm up the medium is fed to the manifold through a specially shaped casing. Mounted on the extended pump shaft, the manifold rotates at the same speed as the pump. The rotating steam nozzles cover the entire cross-section and "plough" through the linear stock flow in radial direction.

Thanks to the large contact surface between the steam and the medium, local overheating of the medium and the resulting condensation surges are prevented to a large extent. Therefore, large steam quantities can be blended into the medium at lowest space requirement and very quickly.

Process Description

Due to its high energy content, steam is used in a variety of processes for heating water-based liquids and stock suspensions.

It is used in several different heating processes. For instance, the pulp and paper industry uses steam. When steam is blown into the medium statically through nozzles, as it is usual, problems will arise due to the high energy content. A solution is the feeding of the steam on as large a surface as possible, but this requires expensive infrastructural measures. The insufficient heat transfer to the stock will still lead to surges and destruction of materials. Conventional steam heating systems do not safely prevent the medium from being partially overheated and deposits from forming at neuralgic points.

Basic Theory

To raise the temperature of 1,000 kg (1 m3) of water by 1 °C, 1.64 kg of steam is needed. At 2 bar steam pressure, this means a volume of 3.57 m3. It means that the volume of the steam needed to heat the medium by just one degree C is 3.5 times the volume of the medium (water). So, to heat 1m3 of water by 20°C, the steam volume needed amounts to 70 m3.

This is where the weakness of static blending system lies. The energy is transferred from the steam to the medium mainly by means of condensation. However, condensation only takes place at the boundary layers between the steam and the medium to be heated.

Dynamic blending reduces this disadvantage, because it increases this boundary layer between the steam and the medium to be heated. This is achieved with steam nozzles rotating inside the medium. The steam nozzles rotate at a speed of 750 to 2800 rpm, so that relative speeds of the steam nozzles versus the medium of up to 20 m/s are achieved. Dynamic steam feeding enlarges the boundary layers between the gaseous (steam) and the liquid phases (medium). The medium's axial flow continuously feeds "fresh" medium to the steam. Also, the steam is distributed in the medium to be heated evenly and finely. This results in rapid and careful heat transfer from the steam to the medium. Large steam quantities can be condensed at lowest space requirement. The steam added condenses immediately without forming bubbles, noiselessly and without condensation surges.

Solutions Realized

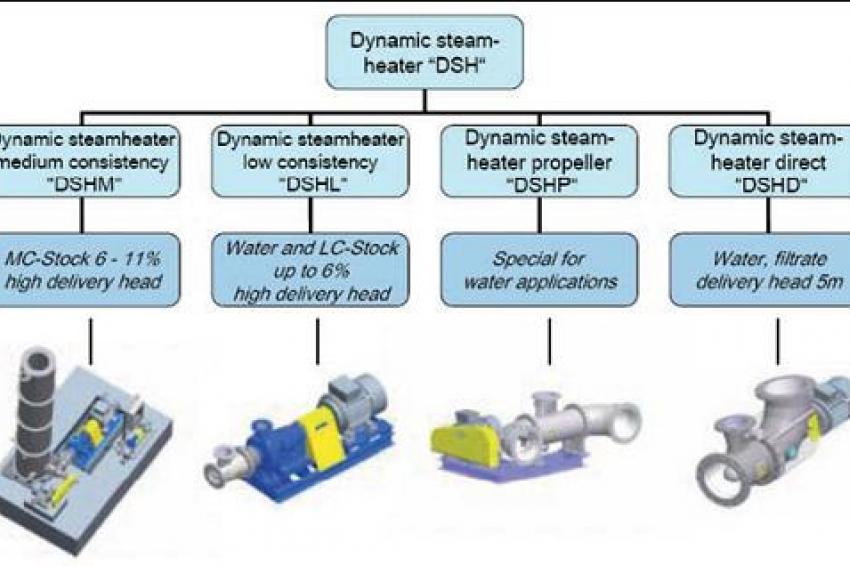

The Dynamic Steam Heater can be applied for different uses in various models. The Dynamic Steam Heater Propeller (DSHP) was developed for feeding very large steam quantities (up to 50 t/h) into a medium. The medium to be heated is conveyed with a propeller pump. Steam rotors are additionally mounted on the pump shaft and rotate at the same speed as the propeller pump.

Practical Use of a DSHP

In this application, the goal was to transfer excess steam from the paper machine for pre-heat VE water in a power station process. In the plant described here, a VE water accumulator with a capacity of 411 m3 is heated from 20°C to over 80°C in just one hour. This corresponds to a heating capacity of approx. 100,000 MJ (28 megawatts). At Adolf Jass Schwarza paper mill in Rudolstadt, Germany, the use of the Dynamic Steam Heater represents a big economic advantage. Use is limited to where the available steam quantity cannot be taken up by the paper machine because of some kind of disturbance, e.g. sheet breakage in the pre or post drying section. Normally, this excess steam would be discharged to the atmosphere via one or several safety valves. This leads to economic losses in two ways: firstly, the quantity of steam released is very substantial, and secondly, the desalinated water must be replaced, at considerable cost. With the Steam Heater, releasing the steam is no longer necessary, because it can be employed to preheat a VE water accumulator. Thus, the Steam Heater pays off quickly.

Considering today's energy prices, if we assume only €25 per ton of steam and the capital investment is approx. €250,000, the Dynamic Steam Heater would pay off already after saving 10,000 tons of steam.

There is yet another positive effect: the pressure in the steam system is maintained.

By blowing the steam into the VE accumulator, the turbine can continue to run in counter-pressure mode in the event of a sheet break and produce the electric power that is needed to avoid energetic peaks (use of pulpers and additional pumps) in the paper mill. When the paper machine again needs more steam, this can be made available immediately, avoiding further expensive peak loads.