From Round-bottomed Flasks to Continuous Flow

Flow Chemistry for Pharma and Fine Chemicals Applications

We speak your language and understand what you need: we speak "catalyst".

Organic synthesis has traditionally been performed in batch processes which include round-bottomed flasks, test tubes or closed vessels such as continuous stirred tank reactors (CSTR). Up to now, continuous flow processes were largely limited to petrochemical and bulk chemical industries, which have dedicated continuous plants and can operate cost effectively.

Recent developments in flow processes for the preparation of fine chemicals, active pharmaceutical ingredients and complex substances have given scientists new opportunities, thus, a brighter future is foreseen in the flow chemistry field, as well as new challenges which need to be addressed.

The breakthrough of continuous flow processing is mainly due to the benefits offered by flow devices over batch processing, and in particular: (a) large surface-to-volume ratios, (b) efficient mass and heat transfer, (c) precise mixing, (d) intrinsic safety, (e) reduced use of solvent and improved stoichiometry, (f) scalability, and last but not least, (g) reduced footprint and operational expenses. All this makes flow chemistry appealing for industrial production.

In addition, flow chemistry can be considered to be a green technology, as the use of flow processing also allows sustainability goals – such as better control of reactant and reagent quantities, reaction conditions (e.g., temperature and time) with energy efficient design, and the possibility of using renewable sources as feedstocks – to be met.

Heterogenous catalysis plays a pivotal role in chemical synthesis at both academic and industrial levels, therefore, both flow chemistry and heterogenous catalysis hold incredible potential from an environmental perspective. Heterogenous flow catalysis would allow greener and more efficient chemistry at an industrial level. Cleaner, safer, and scalable flow reactions could be performed in a sustainable way, with advantages for safety, efficiency, waste reductions, the avoidance of hazardous chemicals accumulation, continuous product formation, and easy recovery and reuse of the catalyst.

However, performing heterogeneous catalysis in a continuous-flow reactor on a relatively small scale and for regulated industries is not straightforward and therefore needs catalyst expertise to overcome technical and regulatory hurdles.

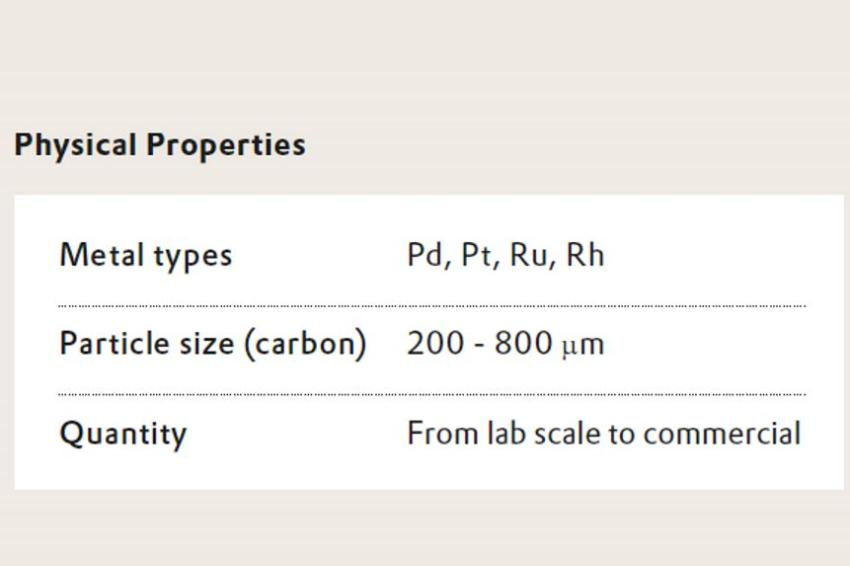

At Evonik we have the ability to fine-tune catalyst selectivity and activity with unparalleled precision. Regardless of the application, Evonik is the right partner to develop catalysts for reactions in flow equipment. By enhancing both the efficiency and yields of your chemical processes, our catalysts can help to produce a larger quantity of the desired product in a shorter period, thus reducing energy and resource consumption.

Evonik offers drop-in catalyst solutions for many existing processes. Thanks to our many years of experience in development and scaling up we can also take your catalyst development to the next level. We efficiently scale up your catalyst lab recipe to full commercial production and ensure reliable supply globally. We are your partner for complete catalyst and process development. And we offer toll manufacturing of your already commercial catalyst recipe. Let’s make a difference with Evonik Catalysts as your reliable partner in all aspects.