Technical Marketing in the Chemical Industry

A Crucial Decision Between Profit And Complexity

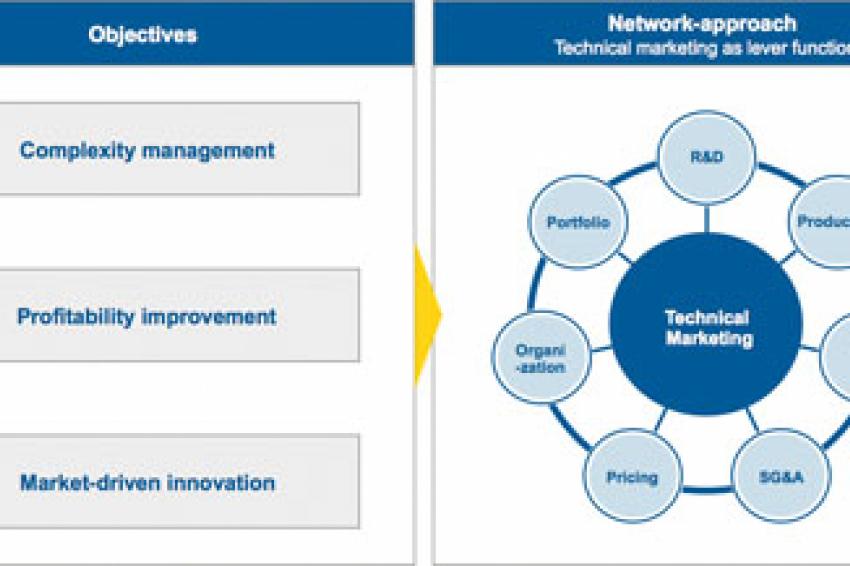

New Meaning - The transformation of the chemical industry into a market-oriented sector has changed the meaning of technical marketing. Today technical marketing has a leverage effect on most areas in the process chain. In most cases, innovation, cost and capital efficiency can be enormously increased by subjecting this area to basic optimization.

The chemical industry has been changing for many years: despite an excellent year in 2010 and a positive outlook for 2011, diverse structural challenges remain, regardless of the many change initiatives in the past two years.

In the middle of the 1990s, the market for chemical products extensively underwent transformation from a seller's to a buyer's market, triggered by an increasing supply from Asia, for the very first time.

In the following years, the "traditional" competitive advantages of western manufacturers such as patent protection, high quality and good availability continued to lose importance particularly in the specialty, fine and functional chemicals sector. At the same time the demand for customized solutions, rendered by products, product formulations or combinations or modified logistics concepts, became more important. In addition, a "commoditization" of products and markets led and still leads to a dichotomy in the value-added chain. On the other hand, specialization and service levels are increasing in other areas, based on the very same intermediate or basic product in most cases.

Consequently, these changes and the attempt to achieve a unique selling proposition in individual areas resulted in a generally stealthy yet massive increase in complexity in many areas, which was reflected, among other things, in high stock levels and rising SG&A expenses.

Observers of the chemical industry in recent years know that it was possible to reduce these costs permanently through appropriate programs only in a few cases and mostly in individual areas such as production or logistics. As a result, capital efficiency (defined as the cash flow-to-sales ratio) e.g. in the specialty chemicals and coatings industry has been below the average industry value for many years.

Technical Marketing As A Driver For Innovation

The focus of this development is technical marketing and its operative element, technical service. This area, which has become more important due to the described transitions from a purely product-centered to a more market-centered industry, gets a great deal of attention when it comes to the development of new products.

Because there are fewer and fewer new chemical structures which lead to new or improved application properties, the share of expenditure on technical service and product development has constantly increased. A recent study by Arthur D. Little with companies from the chemical industry shows that just over 50% of resources for research and development are invested in this area.

The Impact Is Underestimated

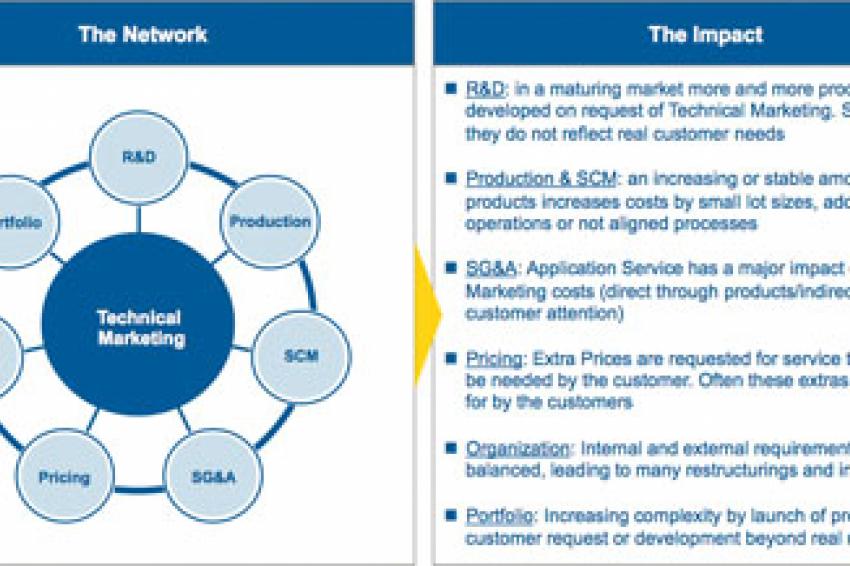

This is only one aspect of the issue, however. The other aspect is the associated impact of technical service on the entire process chain and the cost structures of a company. Contrary to other areas such as production or research and development, this area and its efficiency are still subject to even less scrutiny today. The reasons for this are as follows:

- The significance of technical marketing and service for customer loyalty

- The non-transparency of primarily incurred costs

- The non-transparency of secondarily generated costs

A marketing and sales study shows that 47% of the customers appreciate the service offers and regard them as a distinguishing element. Price (36%) and product quality (17%) only come in second and third in this ranking. Thus service is crucial for a company's success. That is why many companies fear that corresponding optimization can have a negative impact on this sensitive area, with corresponding consequences for the entire company. As a result, there is not only a need to create transparency but also to know the positive leverage effect targeted optimization programs and measures can have in this area.

The second aspect is equally important. While it is possible to identify and optimize manufacturing (production, logistics) and research costs very quickly in a profit and loss statement, the expenditure for technical marketing and service is allocated to many areas and the expenses are comparatively non-transparent.

A Changed Approach

Consequently, it pays off to conduct a comprehensive analysis of the actually generated costs.

However technical marketing sets off a large number of processes and generates a great deal of "secondary" costs or has a lasting effect on them as outlined below.

Cost and capital efficiency can be increased by means of a comprehensive analysis of these factors and their impact on the various elements of the process chain.

The traditional approach via production usually disregards the market. It is optimized internally, without consideration of customers and markets initially. In this case adjustments are often important during the optimization process. Frequently it is required to accept higher stock levels in order to serve the markets despite changed production structures or to even pull out of entire submarkets.

Optimization from the market perspective is initiated with the technical service approach. This involves the scrutiny of customer needs and wishes and the services they generate, such as product diversity, packaging combinations, product variation by means of development and price setting, etc., and working out the actually value-adding elements for the company in the market. This may well be in the customers' interest because provision of satisfactory quality and limited service is sufficient in many areas, whereas expansion of the service components is required in other areas.

A decisive factor in this process is profound knowledge of the market and its requirements which are not always reflected by the wishes of the customer's purchasing departments.

Measures derived from this process therefore lead to comprehensive improvement and reduction of the complexity mentioned above. The monetary result is generated firstly by cost efficiency in important areas such as production, research and technical service and secondly by an optimized product range, lower stock levels and a clear separation of commodities and special products.

This is a long-term process which will be completed over a period of two to three years, not just within a few months. However it will pay off to tackle this process with determination because it not only leads to sustainable improvement, it also enables a change in perspective: from real market requirements to your own processes!

Kontakt

Arthur D. Little GmbH

Gustav-Stresemann-Ring 1

65189 Wiesbaden

Deutschland

+49 611 7148 0

+49 611 7148 290