A Journey towards the Smart Factory

Digitalization Drives Operational Efficiency at MBCC

Towell, an experienced leader of chemical production and operations, believes in adoption of the “right” technology as a key to achieve performance and reduce wastage at plants.

The Mission

In early 2022, Towell and team embarked on a mission to leverage industrial internet of things (IIoT) technology to monitor and track operational performance of the different MBCC manufacturing plants which are distributed across the world. Vegam Solutions, a smart factory solution provider, was chosen as expert to support this multinational project.

Challenges and Approach

Operations specialists at MBCC and Vegam’s staff discussed the constraints and opportunities at hand to implement a solution in a short span of time. Key challenge was the difference in automation maturity across operational units. The parameters measured and the metrics tracked by production plants also varied significantly. Vegam’s smart factory solution offered the necessary flexibility to accommodate automation variations at plants while ensuring standardized parameters and metrics across the board. Integrating performance tracking from pre-existing automated solutions for plants as needed via deployment of IoT sensors and gateways was pivotal to success. For plants opting to use manual recording, Vegam offered mobile applications and easy-to-use tools to record the key parameters.

Working closely with international MBCC teams including operations teams, plant teams and IT teams, Vegam designed an effective and efficient solution built upon its proven overall equipment effectiveness (vOEE) module. Safety and security aspects were discussed in great detail as they present a key concern for the manufacturing industry when moving to a cloud-based application. The proposed solution needed to meet all the IT standards and had to be compliant with MBCC’s corporate policies.

Critical Prerequisites

It was important for Towell and his team at MBCC to onboard a solution offering batch production optimization capabilities. User adoption and change management were key to success. “Our workers have to not only accept a new application, but they have to like it, make it their friend”, expresses a production manager at a MBCC plant in the USA. Structural personnel fluctuation required a speedy migration and easy-to-deploy training and re-training programs.

After careful evaluation both parties agreed to implement the vOEE module. “I can look back at more than 15 years of industry experience in which Vegam co-developed a comprehensive smart factory solution suite (SFS) working closely with leaders in chemical manufacturing. Addressing challenges and complexities of batch production needs has been a regular part of our solution package. That’s why our vOEE module offered a great fit with MBCC Group's requirements”, remembers Subramanyam Kasibhat, founder and CEO of Vegam. Another significant aspect was the replicability of the solution across a targeted number of more than 20 production plants within less than nine months from the project kick-off.

Implementation, Integration and Roll-Out

Both partners quickly agreed to start the work by involving plant staff, IT teams, and software specialists at the identified pilot plant in the USA. Given the Covid-19-related precautions in early 2022, it was agreed to minimize face-to-face meetings to just one visit from Vegam’s CEO at the MBCC plant. A thorough on-site analysis enabled Vegam Solutions to smoothly connect the vOEE module to the existing data logger and related IT environment. Progressively relevant data was uploaded into the cloud-based application. User-friendly output screens focused on overall manufacturing productivity. These process steps resulted in increasing first-time pass rates, reducing downtime and improvements of other indicators critical to the operational performance of any production plant (fig. 1). Initial hesitation of users was anticipated and carefully managed by proactive communication and intuitive application features. Singapore-based Towell saw a great advantage in the close-to-real-time availability of relevant data. He said: “This is visibility at its best. It gives the team and me a solid foundation to make data-driven decisions that will improve our production performance for the benefit of our customers even further.”

Fig. 1: Interior view of a control room at MBCC plant.

The successful results from the work at MBCC pilot plant led to subsequent roll-out efforts in more than 20 production lines across the globe. Translation into multiple languages was readily available. Groundwork was done remotely which made it swift and cost-efficient. Some of the plants used either identical or similar technology which facilitated quick progress. But minor setbacks were part of the implementation as in any projects of this scale. For example, in a few production plants it was difficult to iron out some of the connectivity issues which can at times result in latency or incomplete output. To overcome the obstacles highest commitment on both sides was essential and led to a timely issue resolution and completion of all workstreams within the project schedule.

Short Amortization Period

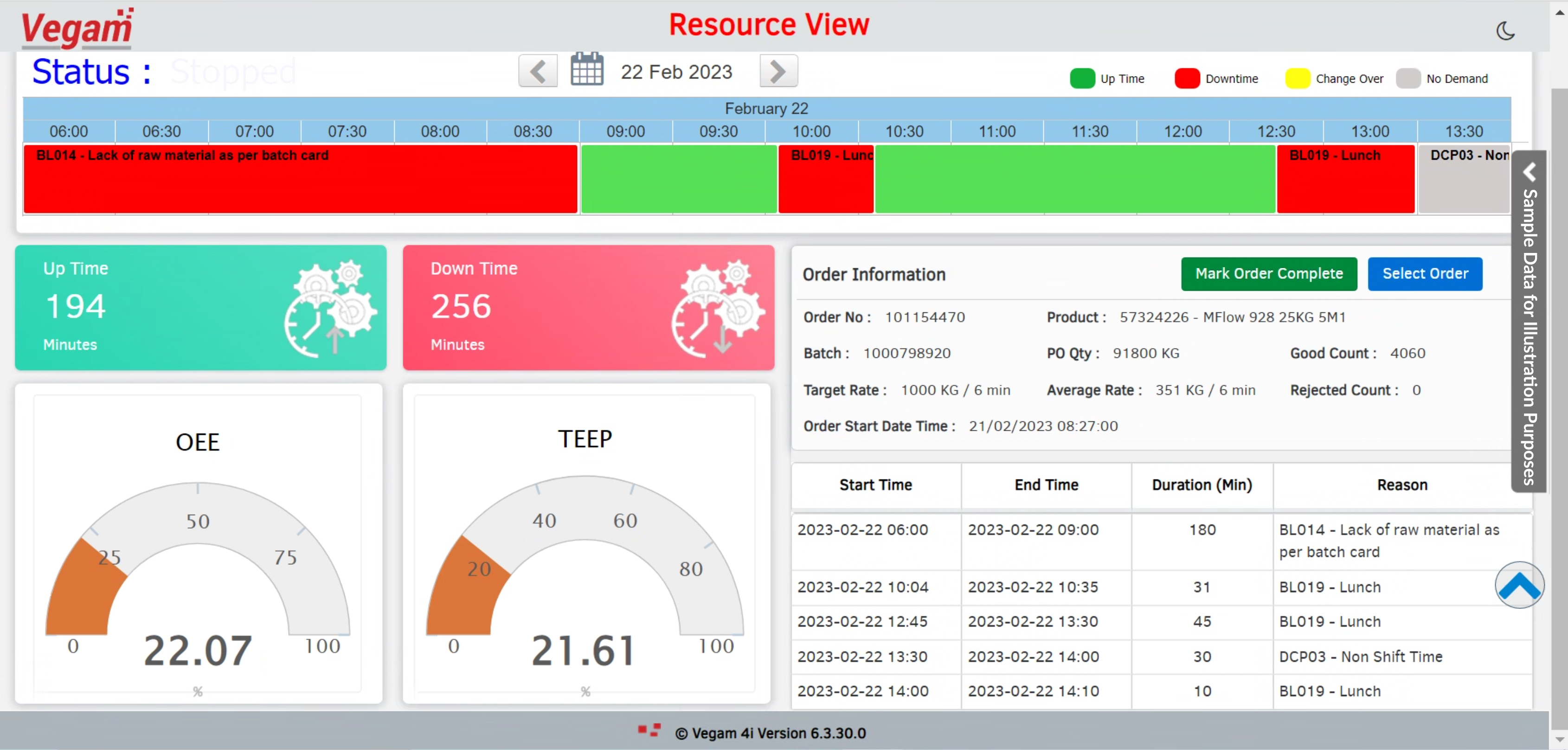

The introduction of such an impactful software solution needs a close commercial assessment. Discipline in achieving the agreed milestones from the kick-off is paramount. Vegam and MBCC chose a software as a service (SaaS) model with clearly defined costs per production line. One-time costs for installation and integration were additional cost components. MBCC evaluated these expenses against the many benefits such as increased uptimes, avoiding waste, and reducing energy costs. The amortization time was less than 12 months after its successful implementation, even though the availability of resources, such as experienced production workers, process engineers, and IT specialists, was a primary bottleneck in this project. “Nobody is sitting idle and waiting for us to come and start the implementation work”, expressed Subramanyam. “I highly appreciate the impressive workload of qualified resources at the production plants as we needed to adapt our solutions as quickly and smoothly as possible to the existing environment.” Towell added that “user-friendliness is key, always!” He also mentioned that after a short instructional phase of two to three weeks his team ought to be able to use the solution independently from third-party’s help (fig. 2).

Fig. 2: Dashboard of Vegam Solutions' software solution:

Outlook

Based on the experiences with the vOEE software MBCC have expressed their desire to introduce additional Vegam smart factory modules in their production plants, such as digital maintenance, predictive maintenance and condition-based monitoring. These are high on Towell’s list of priorities. “Having this level of transparency across operations from wherever I am raises the dialog with my teams to a distinctly higher level of quality. I am looking forward to the next steps with Vegam Solutions who have proven their agility and problem-solving capabilities to MBCC Group.

Contact:

Wayne Towell, Vice President of Operations, MBCC Group

wayne.towell@mbcc-group.com

https://www.mbcc-group.com

Subramanyam Kasibhat, CEO and Founder, Vegam Solutions

subbu@vegam.co

https://vegam.co