Processes4Planet: EU Cross-Sectorial R&I

Ten Sectors of the European Process Industry Deliver Innovation for Society and the Planet

The European process industry is engaged in a deep transformation to deliver the green industrial revolution. With climate change pushing the investment agenda, the urgency to drastically reduce CO2 emissions will drive process industry decisions in the years ahead. How can the process industry contribute to the very ambitious targets set by the European Green Deal and the Paris Agreement?

Climate change is visible in every inhabited region in the world and the sense of urgency must permeate the actions of the entire socio-economic system, according to the Sixth Assessment Report 2021 of the Intergovernmental Panel on Climate Change (IPCC). Despite the need for wide and deep action in the next two decades, according to Jeffrey Sachs, the financial system and larger countries have so far failed to capitalize the hundreds of billions of dollars needed annually. On June 2021, at the Tri Hita Karana (THK) Climate Forum, Sachs pointed out that we need a second Bretton Woods and he called for the G20 Bali Summit 2022 to be such a historic breakthrough for humanity: the “Bali One” that can trigger a real global green economy.

Besides climate change, feedstock dependency and resilience will also dominate our future economic system. Given the limited timeframe (only about two investment cycles are left until 2050), for the ten sectors engaged in the Association SPIRE (A.SPIRE), there is only one way: work together to find joint cross-sectorial solutions to common problems.

Process Industry: Highly Ambitious R&I Agenda

A.SPIRE, representing the EU Process Industry, is the private partner of Processes4Planet (P4Planet) R&I Partnership formalized through a Memorandum of Understanding (MoU) with the European Commission. The MoU constitutes an agreement to undertake all efforts necessary to jointly develop and finally deliver the required solutions on climate neutrality, circularity and competitiveness identified in the P4Planet Strategic Research and Innovation Agenda 2050 (SRIA), developed by the A.SPIRE community.

“No single technology can reach 100% greenhouse

gases (GHG) emissions reduction on its own.”

The process industry is key to achieving this transition. Reaching a net-zero scenario by 2050 and holding the increase of the earth’s temperature well below 2°C will require the delivery of climate neutral and circular solutions at an unprecedented scale and pace. Improvements in emissions reduction at materials processing plants has a multiplying effect across different value chains (automotive, construction, digital devices et al.). The energy-intensive industries also have the capacity to reintroduce bulk amounts of waste transformed into new secondary resources to feed industrial processes, avoiding landfilling or incineration. The challenge for this recycling is to do it with fewer emissions and less cost compared to the use of virgin materials to remain globally competitive.

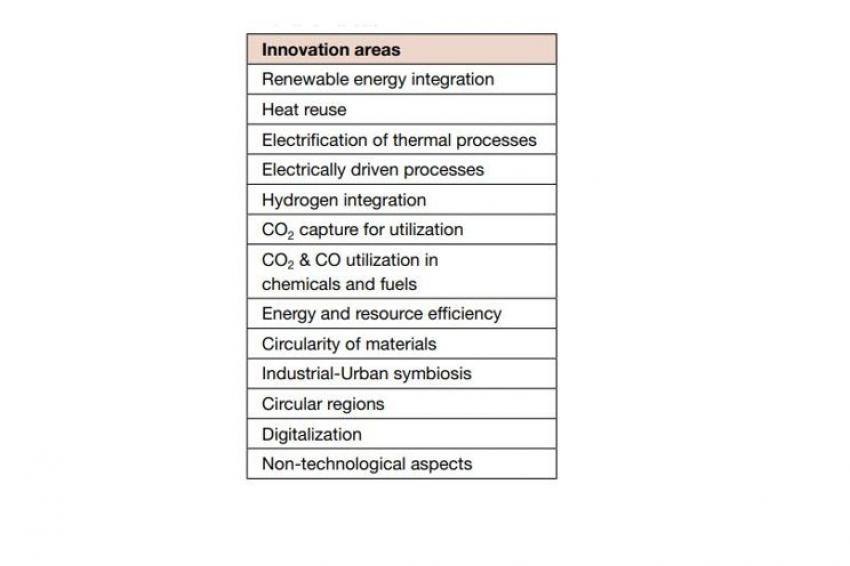

P4Planet’s Strategic Research and Innovation Agenda (SRIA) sets three high ambitions for 2050: 1) net-zero greenhouse gas emissions; 2) near zero landfilling and near zero water discharge; and 3) a thriving EU process industry with gross value added (GVA) growing quicker than EU gross domestic product (GDP). The SRIA identifies 14 Innovation Areas and 36 Innovation Programs to develop the required solutions (see tab. 1).

To achieve net-zero emissions, P4Planet’s SRIA includes solutions to move from fossil fuel emissions to the electrification of the process industry through an increased use of renewable energy and the valorization of process emissions. This will involve adapting processes to cope with alternative resources, reducing energy needs and other disruptive innovations. To achieve the circularity ambition, we need to move from waste to resources at scale, by keeping resources with the right quality in the industrial loop as opposed to landfilling or incineration. The eco-design of materials that are free of toxic elements is important so that, soon, nearly 100% of waste can be upcycled.

“Improvements in emissions reduction at materials processing

plants has a multiplying effect across different value chains.”

Since competitiveness is at stake, non-technological aspects are equally relevant. Identifying and raising awareness of the public sector on the framework conditions for market uptake will be key to creating a market for climate neutral and circular solutions. Manufacturing industry, under pressure from consumers, will increasingly ask for materials that are safe, high-performance and with lower carbon footprint. And competitiveness can only be achieved by having the right talent at all levels of an enterprise (from the operational sites in the plants to the blue-collar jobs etc.). The learnings from P4Planet’s projects on these aspects will be key to raising the voice of A.SPIRE members in discussions with the European Commission, the European Parliament and EU Member States.

Sustainable Investments for Impact

The transition to climate neutrality and a new paradigm of green and circular economy will only be reached when these solutions are rolled out. This is when impact happens. Two key initiatives are included in P4Planet’s SRIA to reach this impact phase. No single technology can reach 100% greenhouse gases (GHG) emissions reduction on its own. They need to be integrated in First-of-a-Kind (FOAK) processing plants, and FOAK units within existing plants, that can completely transform the industrial processes. Such integration can deliver the next generation of the energy intensive industries with a drastic reduction of GHG emissions. Hubs for Circularity (H4Cs) are the second initiative focusing on the generation of impact in specific industrial sites or regions. The H4Cs aim to scale up a new model of circular economy, enabled by the process industry (closing the circle), that makes the best use of all the resource streams (energy, materials, data etc.) from industry and from municipal waste.

“Digitalization will accelerate faster development

of novel solutions by the process industry.”

The EU process industry estimates at least €34.5 billion are needed to develop the required innovations up to 2050; of which at least €19.8 billion need to be invested within the next decade to reach the EU Green Deal Targets. The P4Planet Partnership will play a key role in providing funding and financing support to de-risk the required innovations to transform the process industry. Following the MoU with A.SPIRE, the European Commission has allocated a €1.3 billion funding envelope within Horizon Europe (2021—2027), the current EU R&I program, to support projects that will address the ambitions of the partnership. Horizon Europe supports innovations at pre-competitive level. Further support to the FOAKs and H4Cs at scale will also be regularly discussed with institutional funding and financing bodies to reach the deployment (impact) phase. The estimates for investment for roll-out point to the need for hundreds of billions or even trillions of euros. A high sustainable private leverage will be key to achieving the level of investment required.

Enabling the Transition to a Green Economy

Electrifying the process industry through renewable energy and green hydrogen can enable the drastic abatement of industrial CO2 emissions provided there is enough clean energy available at an affordable price. The success of the energy sector can enable the process industry to achieve its climate ambition. In turn, electrification of the industrial plants will imply a higher electricity demand. This high demand from the process industry can enable a competitive clean energy transition. Energy efficiency is also at stake. The process industry will play a key role in testing how to use the mix of renewable energies more efficiently and flexibly, enabling such practices along the whole value chain.

“The EU process industry estimates at least €34.5 billion are needed

to develop the required innovations up to 2050.”

Digitalization will accelerate faster development of novel solutions by the process industry. A holistic approach is needed for a more intelligent operation of installations and all business and industrial processes. It is important for the process industries to collaborate with key digital companies that can target digital innovations (artificial intelligence, smart data, cybersecurity, digital twins, etc.) to the specific needs of process operations and the various value chains (including the full recycling, tracking, and tracing). It is also important to attract digital talent to the process industries to help them accelerate their transformation. A systemic perspective will enable the achievement of a real circular economy paradigm and will require the involvement of the full value chain.

Conclusion

The energy intensive industries are highly engaged to pledge for climate action. The challenges they face are cross-sectorial and some solutions are sector specific. Processes4Planet is an essential tool for A.SPIRE’s ten process industry sectors to maintain a cross-sectorial dialogue and jointly develop R&I solutions that can be transferred from sector to sector to meet these pledges. The process industry, united, is stronger and can deliver higher targets.

References for this article can be requested from the authors.

Ludo Diels, Chair of Advisory Group, and Àngels Orduña,

Executive Director, A.SPIRE,

Brussels, Belgium